Ciarán Murphy

I'm a Mechanical Engineer with red hair.Startup Founder, Hardware Product Specialist, Nerd Generalist.Based in San Francisco.

Projects

Skills

Fields I've Worked In

Consumer Electronics

Robotics

Health and Wellness-tech

Contract Manufacturing

3D Printing

Green-tech

Art-tech

Early-Stage Startups

PM Competencies

Hardware Product Managment

Project Managment (PMP in progress)

Waterfall Methodologies

Agile Methodologies

New Product Introduction

EVT, DVT, PVT validation

Statistical Process Control (Certified)

Mechanical Engineering

Onshape (Certified Professional)

Solidworks

Agile PLM

Jobboss ERP

Design for Manufacturing/Design for Assembly

Geometric Dimensioning and Tolerancing

Injection Molding

Sheet Metal

Supply Chain Management (OEMs, ODMs, JDMs, CMs, USA based and abroad, etc)

Prototyping

CNC Machine Tools

Manual Machine Tools (Mill, Lathe, Drill Press, etc)

3D Printing (SLS, SLA, FDM, etc)

Arduino

Soldering

General Software

Google Suite

Microsoft Office

Notion

SmartSheets

BaseCamp

ClickUp

Linear

Intercom

Jira

Development Software

SQL

Python (some)

Airtable

Git

Arduino

Other

Long-form Improv Core Curriculum (Upright Citizen's Brigade Theater)

Licensed Ham Radio Operator (KD2KFH)

Contact

Employment, projects, general inquiries? I'm also quick to respond via LinkedIn.

Patents

| Number | Description | Notes |

|---|---|---|

| US10528032B2 | Systems and Methods for Generating a Patterned Orthotic Device | Current |

| US10993588B1 | Dispensing Device With Disposable Insert | Current |

| US20160101571A1 | Systems and Methods for Generating Orthotic Device Models By Surface Mapping and Extrusion | Abandoned |

Personal Projects

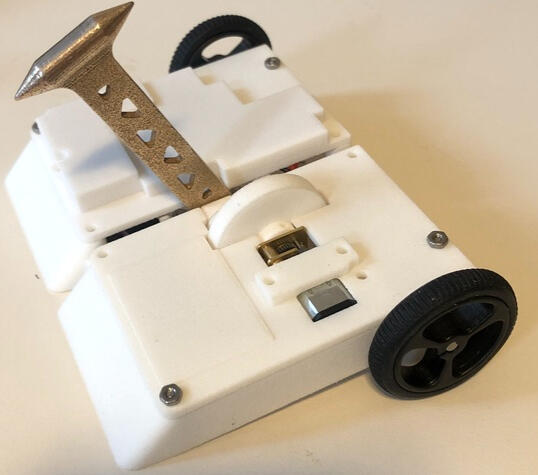

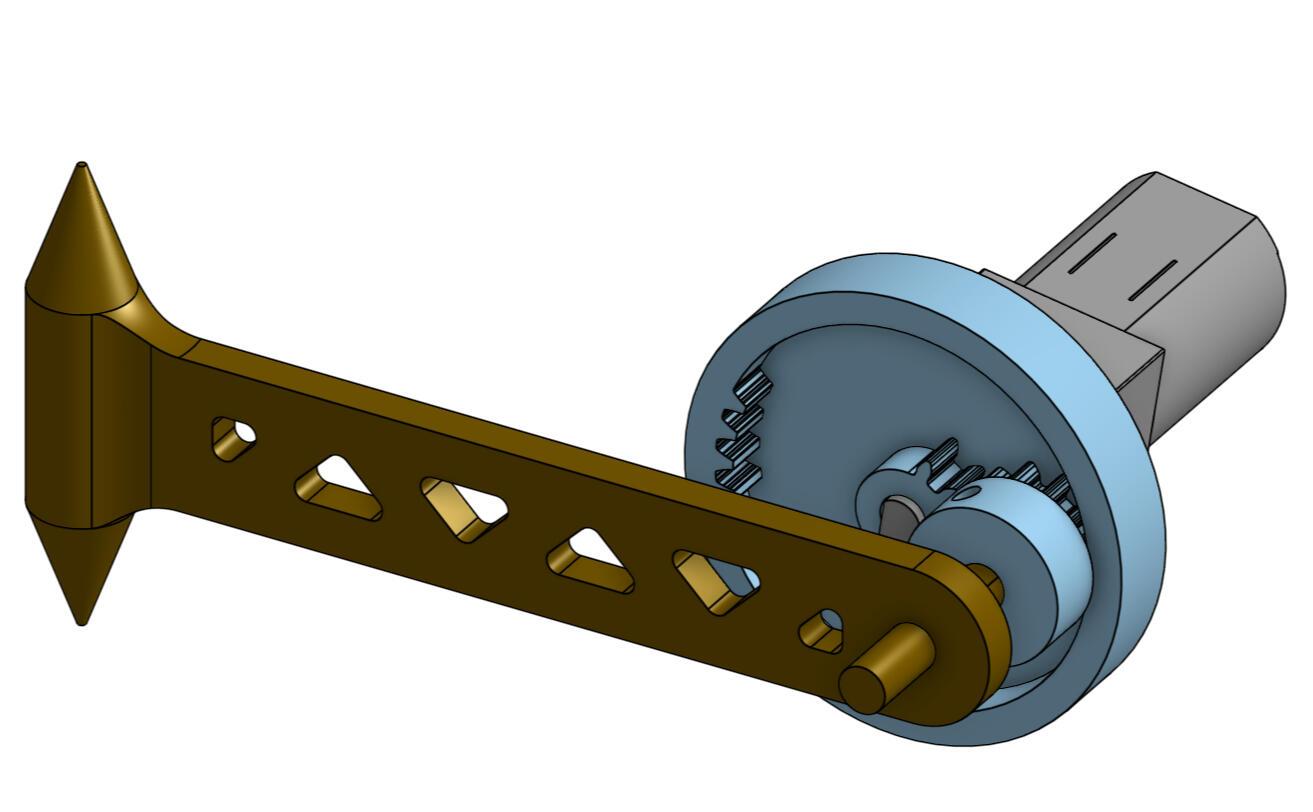

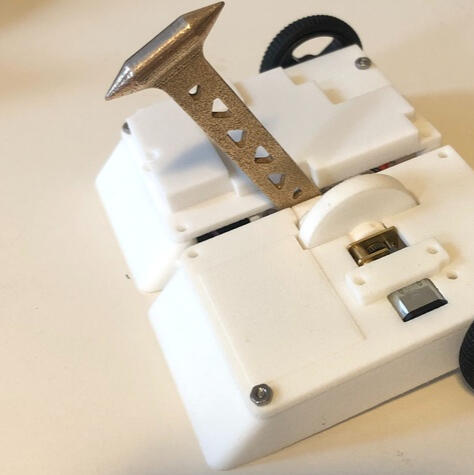

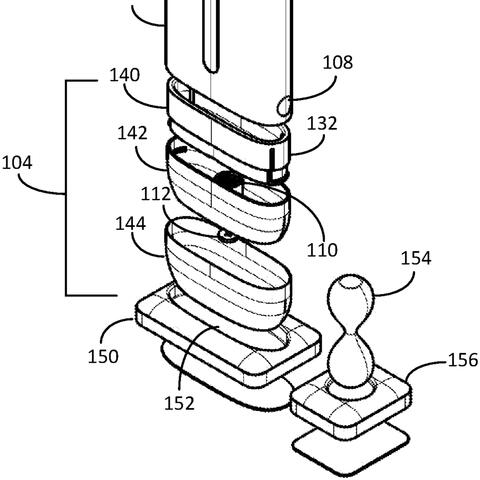

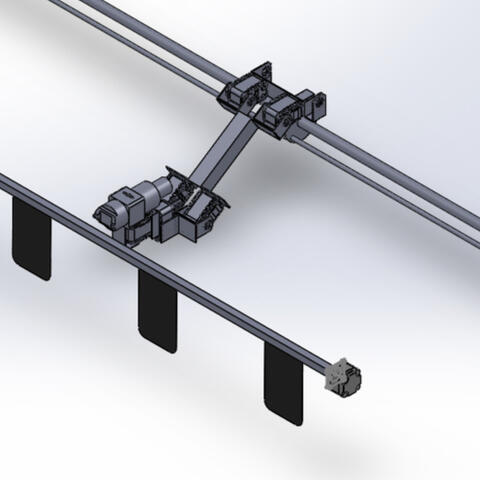

Combat robot: "Horse Detective"

150g robot built around a sprinkler-style reciprocating gear and a hammer. Designed to be "weird" instead of "effective".Normally, a hammer-robot requires the driver to control each swing. One command is sent to run the motor forwards (to strike) and another is sent to run the motor backwards (to retract). My brain doesn't work that fast.This robot's reciprocating gear allows the hammer to operate automatically. For half of the motor's rotation, the hammer is driven by teeth facing outwards from the interior of the gear. This causes the hammer to strike forwards. During the other half, the hammer is driven by teeth facing inwards from the exterior of the gear. This causes the hammer to retract. As long as the motor is on, the hammer strikes and retracts itself.Unfortunately, the 150g weight class is rare these days, so this robot remains untested in combat.

Work Projects

Openshelf,

née Perpetual Solutions,

née Openshelf

More Information Coming Soon

Sero Health

Remote, Tactile EMDR Therapy

Co-Founder

Contents

Accomplishments

Invented "Sero Stones", the first IoT devices for "Remote, Tactile EMDR Therapy".

Led development of the Sero app (native iOS)

Acquired a waitlist of 1700+ EMDR therapists for Sero Stones.

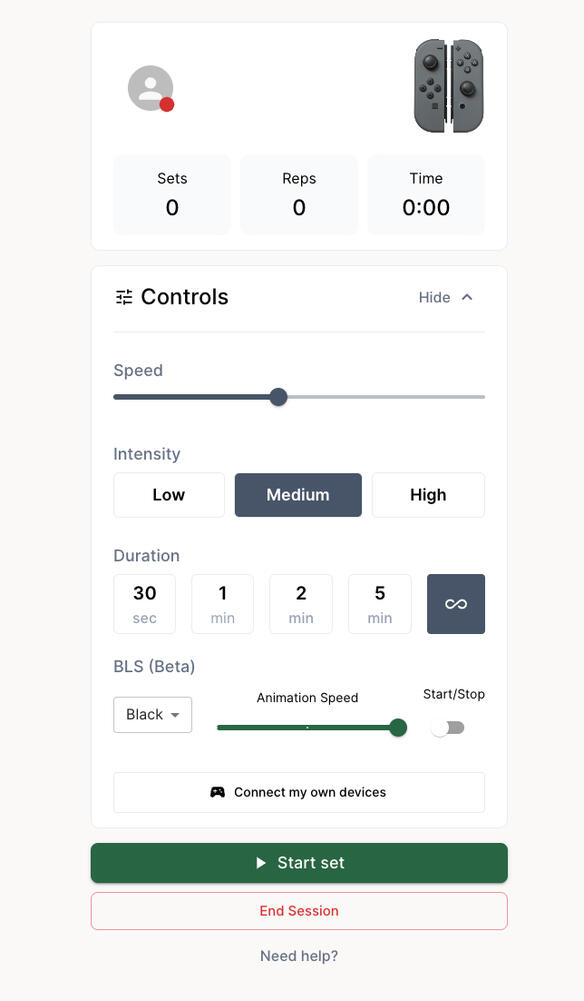

Released "Sero Beta": an EMDR web app based on Nintendo Products.

Grew Sero Beta consistently 20% Week Over Week.

Ensured HIPAA Compliance

Skills Used

Agile Product Management

User Research/Analysis

KPI Development

Onshape/CAD

DFM/DFA

Supply Chain Management

Startup Founding and Fundraising

What is Sero?

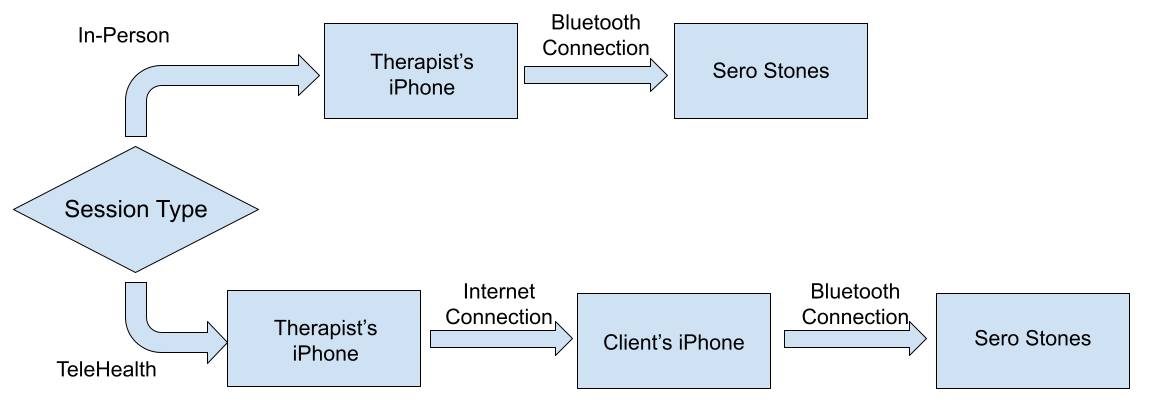

Sero enables access to tactile EMDR therapy — the fastest growing PTSD treatment — anywhere in the world. Our product, Sero Stones, allows therapists to treat clients with tactile EMDR no matter where they are.

What is EMDR?

For more information about EMDR and why it uses devices, check out my "About EMDR" page, below (warning — it's a wall of text).TL;DR:

EMDR stimulates each side of the body (alternating left and right) during therapy.Vibrations controlled by the therapist are an ideal way to provide these stimulations.Therapists adjust the vibration intensity and speed of switching sides depending on the therapy's progress.Existing devices ("tappers") were wired, limiting telehealth use.

Sero Strategy and Product Management

For information on:

How we performed research and developed customers

How we positioned the company

Product Requirements

Product Management and KPIs

How we sold devices

Our academic partners and government funding submissions

About choosing "medical" versus "wellness" device directions

Future Sero plans

Click here:

Sero Stones and the Sero App

Here's the history of Sero Stones and the Sero App:

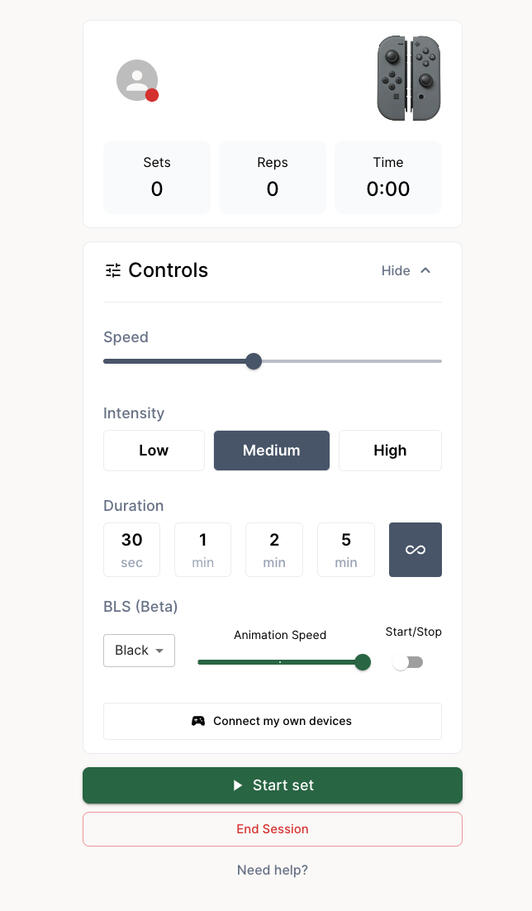

Sero Beta

We also built entry-level EMDR software built on top of Nintendo Joy-Con controllers, called Sero Beta. Here's that story:

Demos

Sero Stones

Sero Beta

About EMDR

Contents

What's EMDR Therapy?

EMDR therapy is one of the most popular and effective trauma treatments, but accessing it has been notoriously difficult. The tools used in treatment today simply aren’t designed for telehealth.EMDR is a type of therapy that involves a therapist guiding a patient to focus on a distressing memory or experience while simultaneously engaging in bilateral stimulation (alternating stimulus of the left and right side of the body), such as eye movements, tapping, or sounds. This is thought to help the brain process and reframe the traumatic experience in a more adaptive way, reducing the emotional distress associated with the memory.

Why use devices?

Therapists and their clients typically prefer tactile EMDR instead of visual or auditory options. Reasons for this preference include:1. Reduced need for eye contact: Eye movement-based BLS can be challenging for people who have difficulty making eye contact or experience discomfort with prolonged eye contact. Tactile BLS does not require the patient to make eye contact with the therapist, which may make the therapy more comfortable and accessible.2. Greater physical sensation: Tactile BLS involves physical touch, which can provide a greater sensation and sense of grounding than other forms of BLS. This can be particularly helpful for patients who have difficulty staying present in their body or experience dissociation.3. Flexibility: Tactile BLS can be easily adapted to a patient's individual needs and preferences. For example, the therapist can adjust the intensity and location of the tapping or use a different form of physical stimulation, such as gentle vibration.

How is EMDR different than other therapies?

Unlike other therapies including Cognitive Behavioral Therapy (CBT), EMDR does not require (a) detailed descriptions of the event, (b) direct challenging of beliefs, (c) extended exposure, or (d) homework.Instead, EMDR therapy is designed to resolve unprocessed traumatic memories in the brain and allows the brain to resume its natural healing process. For many clients, EMDR therapy can be completed in fewer sessions than other psychotherapies.

Is EMDR Effective?

Initially developed in the 1990’s, EMDR has been extensively clinically validated by 50+ randomized controlled trials (RCTs). It is widely considered to be the gold-standard for PTSD and trauma-based mental health conditions.Both USA-based (Veterans Administration, American Psychological Association, etc) and international organizations (like Britain's NHS and Psychological Society) promote EMDR for PTSD treatment.In a study performed by the University of Miami, EMDR was compared directly to Prolonged Exposure (PE), another widely-used trauma treatment. EMDR was found to work more effectively (70% of EMDR patients reported initial positive results after three sessions, compared to 16.6% of PE patients). EMDR is also considered better tolerated (0% of the patients left EMDR treatment, compared to 30% of PE patients). At a long-term follow up test, results were found to be maintained.Another study from Boston University compared EMDR to both Selective Serotonin Reuptake Inhibitors (the most common medication prescribed for mental health) and a placebo. At a six-month follow up, over 83% of EMDR patients were found to be asymptomatic, compared to 0% for the other groups.

What does the competitive landscape look like?

These tools (from Neurotek, EMDRKit, and TheraTapper) represent the existing top-of-line EMDR product. They are unintuitive and cannot be used by the client or remotely.

Sero Product History

Contents

Sero v1.0: Hackathon Weekend

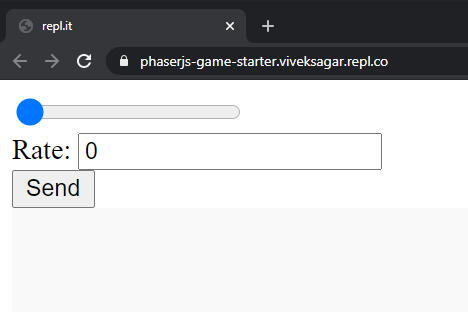

I founded Sero along with Tyler Beaty while were both in the On Deck program and looking for a project for an upcoming weekend hackathon. With my hardware background, I knew I wanted to work on a physical product, and he had an idea.Tyler was receiving EMDR therapy at the time, and wanted to practice at home. Unfortunately, the devices he used (or "tappers") were meant to be used in the office. Making something better seemed like an achievable weekend project, and given my own history with therapy, I found it easy to get on board.Over the course of the weekend (and with the rest of the distributed team), we hacked together "Pebbles":

A PS4 controller acted as the guts and brains of Pebbles. How many other devices out there involve Bluetooth and multiple motors?The telehealth interface was based on Unity, but looked less elegant (though it worked):

Fore more information on app development, check out the Sero Software page.With a successful live demo, we won the "Most Likely to be a Unicorn" award.

Customer Research and Product Requirements

The success of the weekend made us realize that we might have something worth working on.Since neither of us were therapists or neuroscientists, we had to develop deep user expertise as we went.The first few weeks were spent interviewing dozens of therapists (and eventually hundreds). We needed to understand how they practiced EMDR, how they learned about EMDR, and what was missing from their existing tappers.For the most part, they agreed that the existing tappers were not sufficient, especially for telehealth. These requirements were critical:

Totally wireless

Remote capable

Five hours of battery life

Easily graspable by a child

Integrated lights for visual stimulus

Vibration strength must be on par with existing products. (See the About EMDR page for examples of competitors).

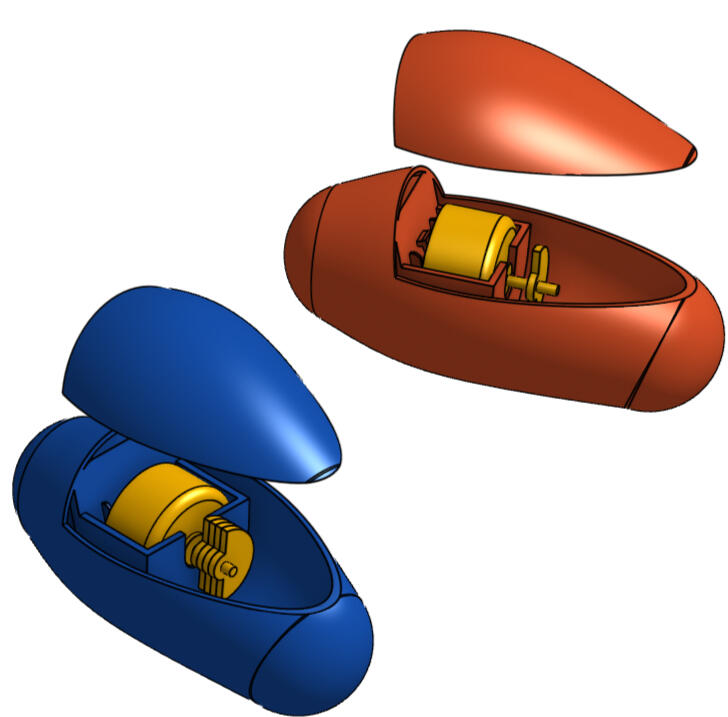

Sero Prototypes — v2.0

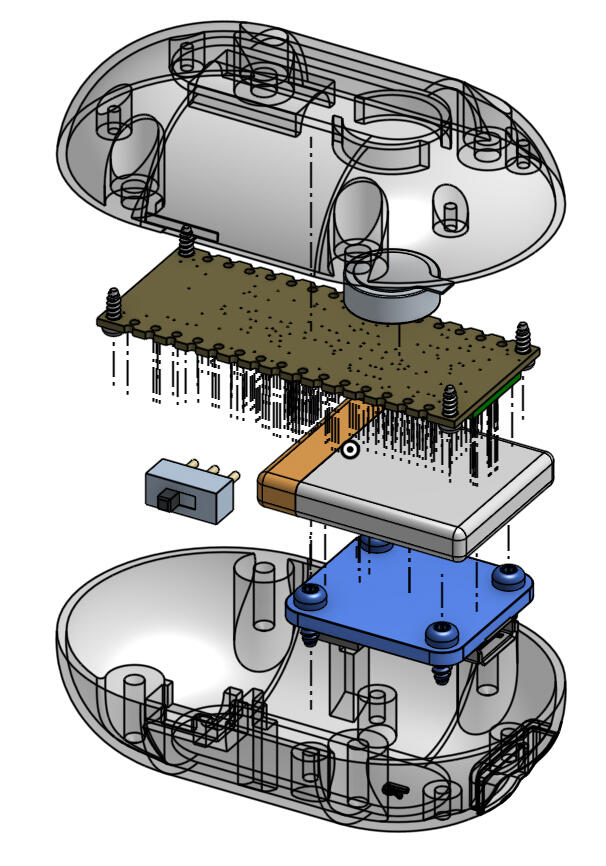

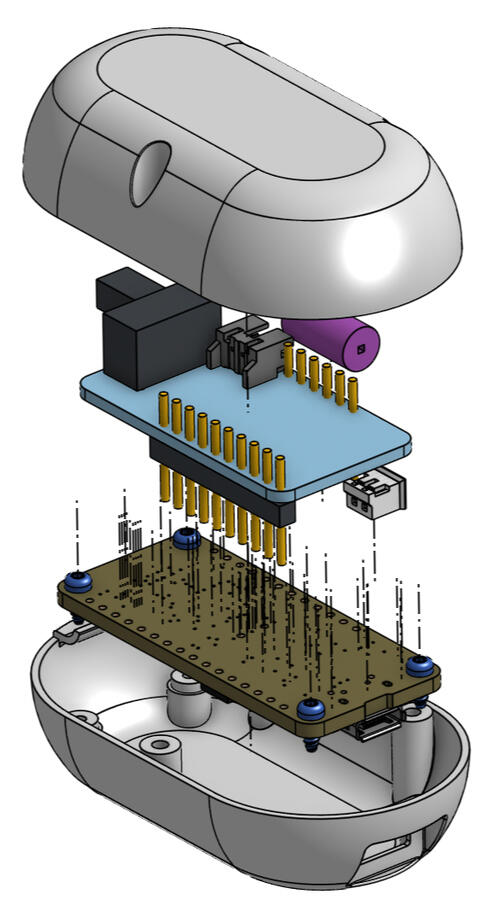

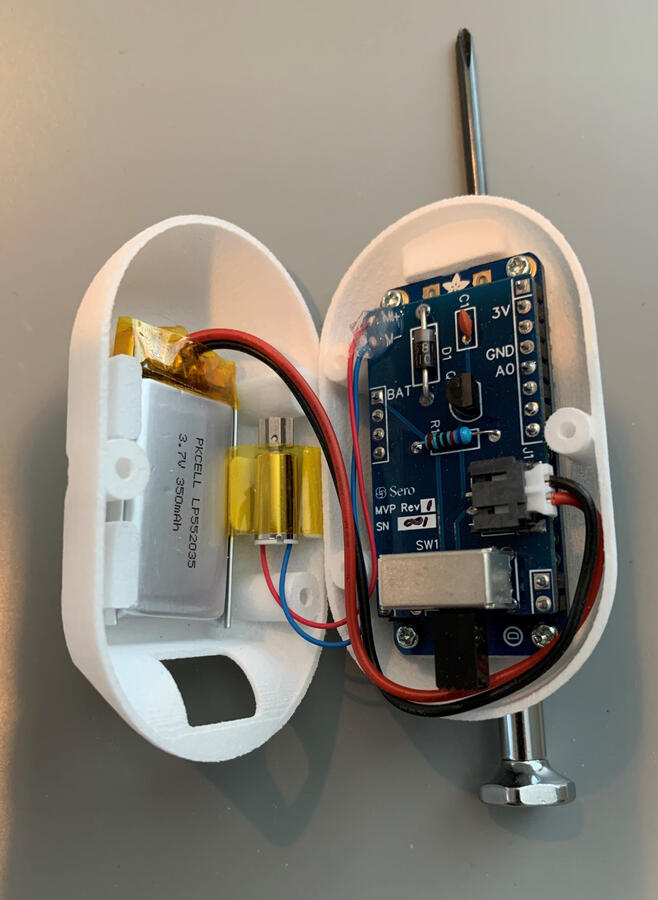

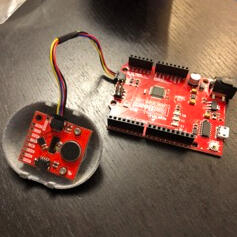

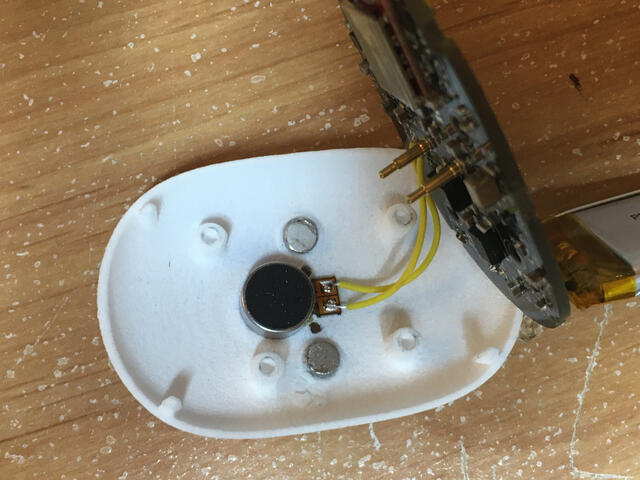

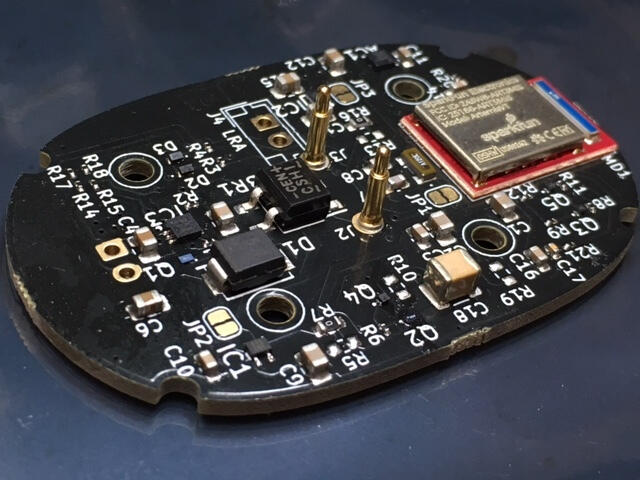

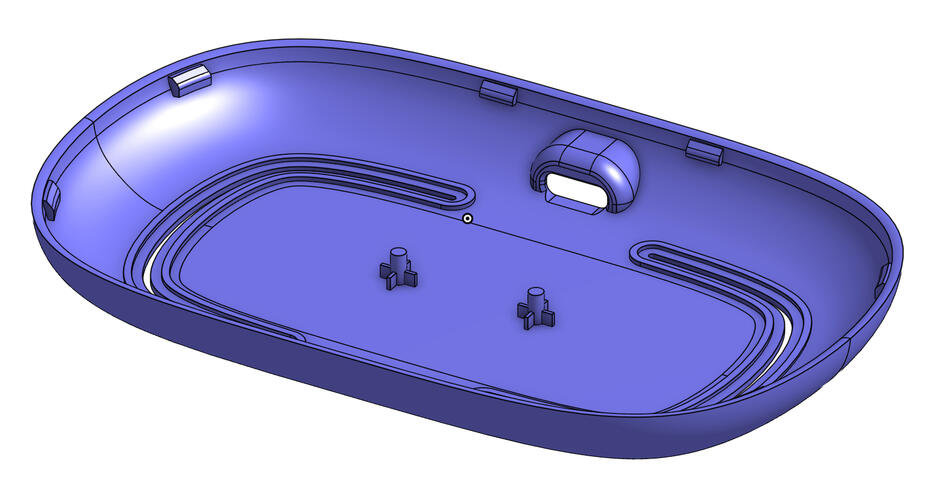

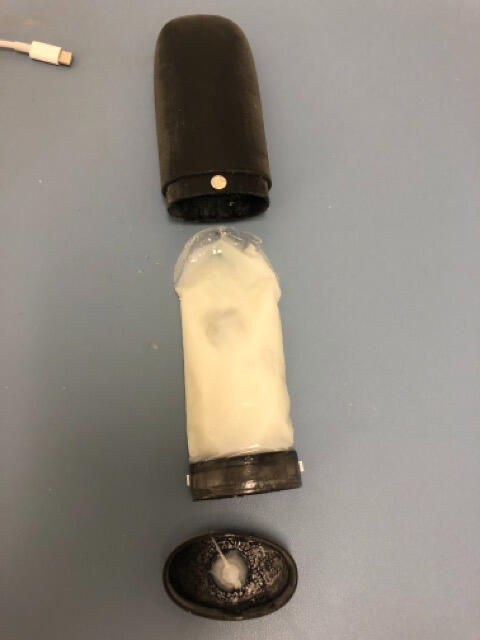

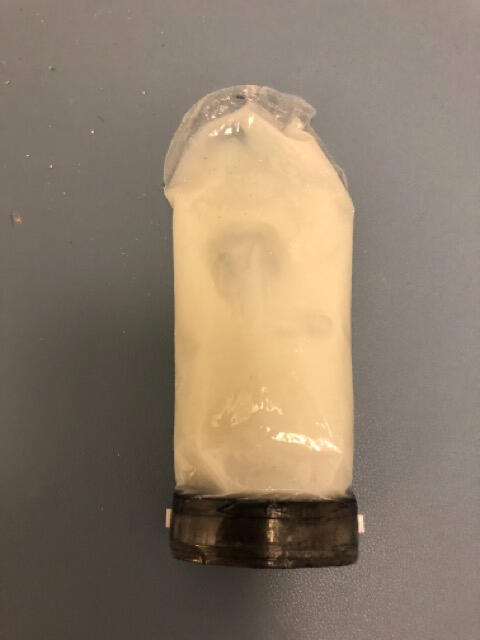

With that, the team set out to create a batch of functional prototypes that used 3D printed housings and off the shelf electronics (namely a Arduino Nano 33 BLE, vibrating motor, and charging circuit):

Sero Prototypes — v3.0:

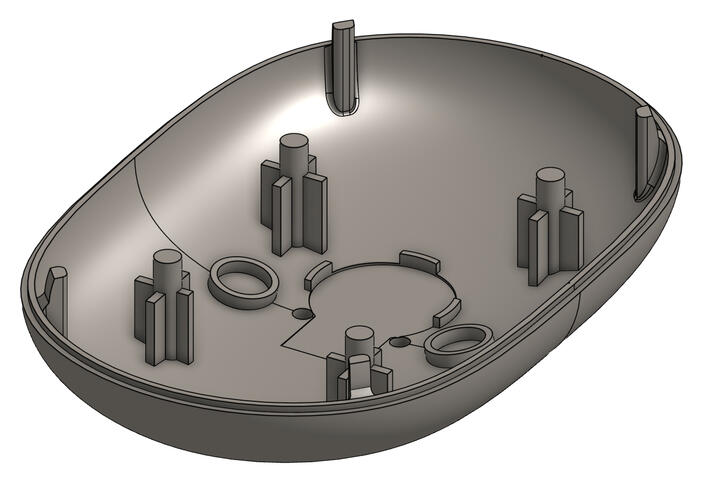

Things were looking great, until thieves stole the prototypes from my apartment building.The silver lining here was that we already knew we had changes we wanted to make.So we hired an electrical engineer to ensure that our our circuit and our firmware were solid (including a better charging circuit with an integrated switch), and created a housing that was easier to assemble:

These models were delivered to dozens of therapists and their clients, performing hundreds of EMDR sessions. Overall, they were well received, but gave us plenty of feedback about where to improve.

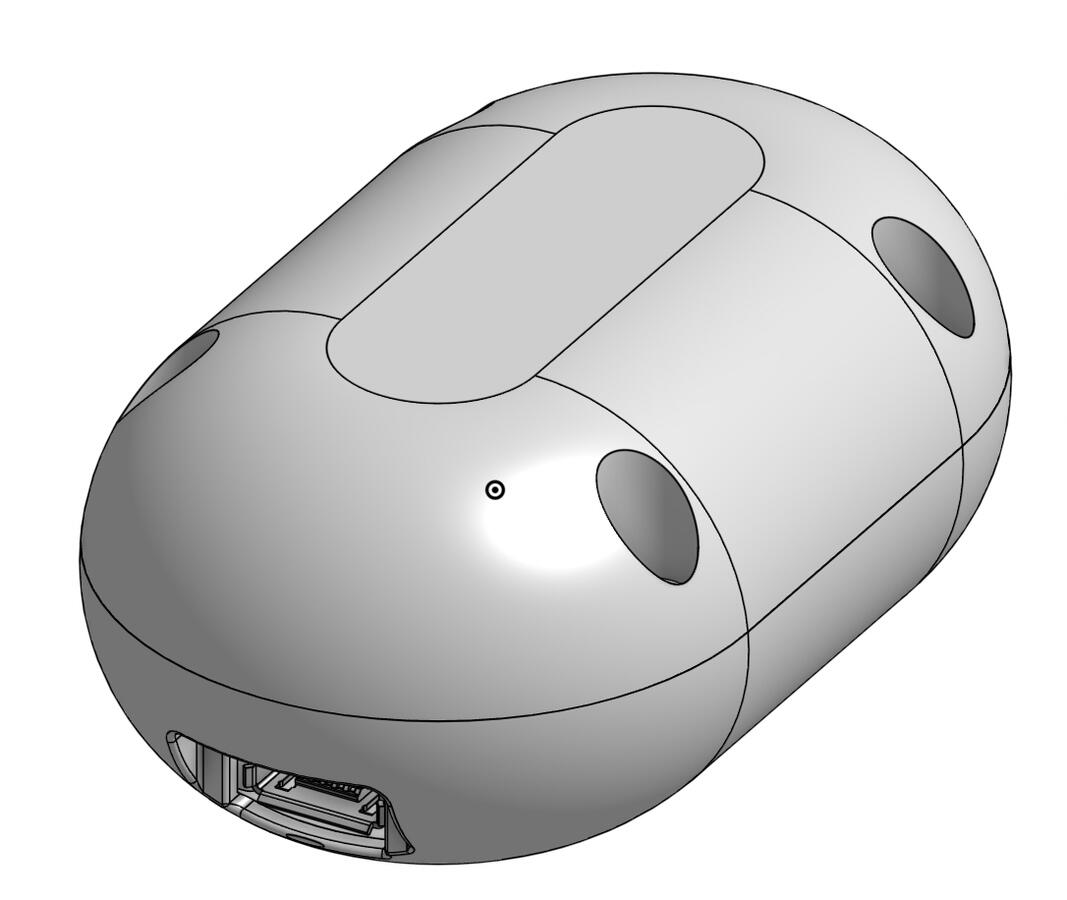

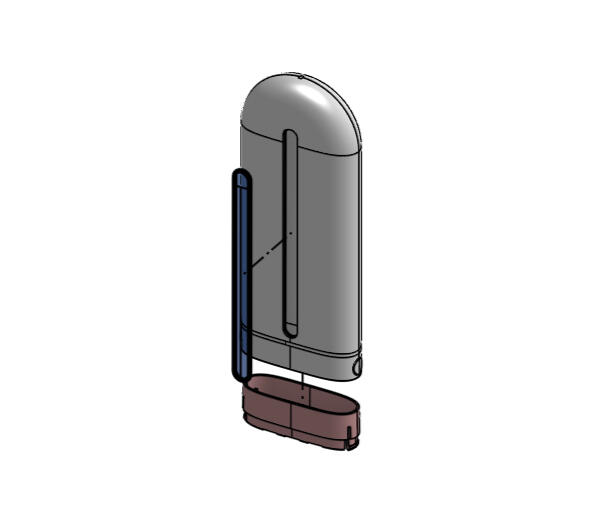

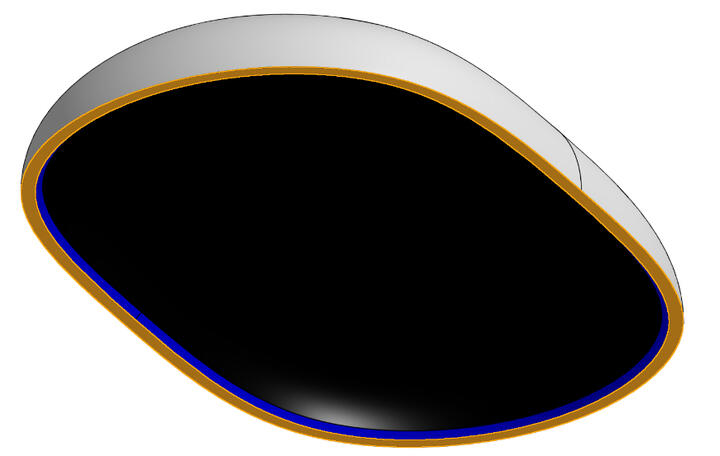

Production Sero Stones

After reviewing the notes of the beta units, we knew what we needed in order to create marketable EMDR devices. Major requirements included:

50% smaller than our prototypes

A Linear Resonating Actuator (LRA) instead of a vibrating motor (to create new tactile stimuli)

Stimulation strength on par with existing EMDR devices

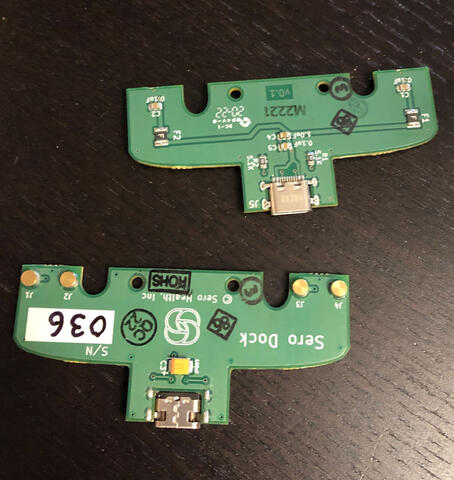

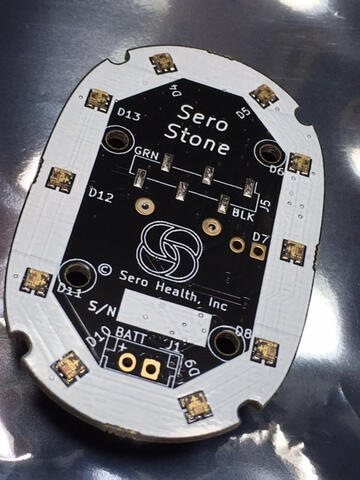

Consolidated, custom PCBs

Charging pad with magnetic placement (to eliminate USB cables)

Vibrant lighting

Battery life reporting

Compatible with our new app

"Sleep Mode" (to eliminate power switch)

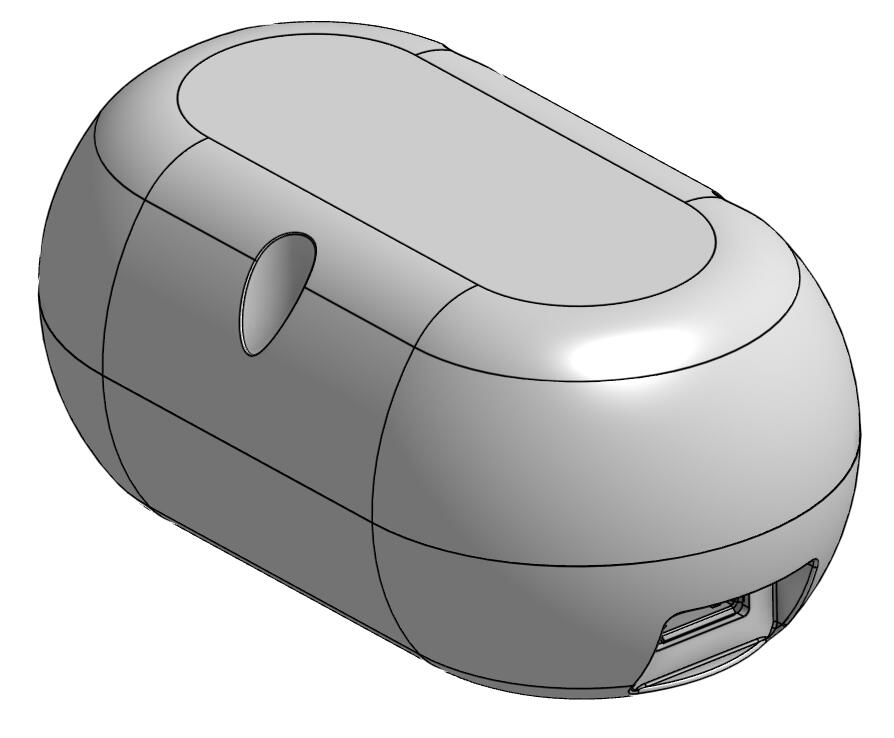

Distinctive, soothing appearance inspired by nature (unlike competing devices)

Standard regulatory and environmental requirements

Support for Over-the-Air Firmware updates

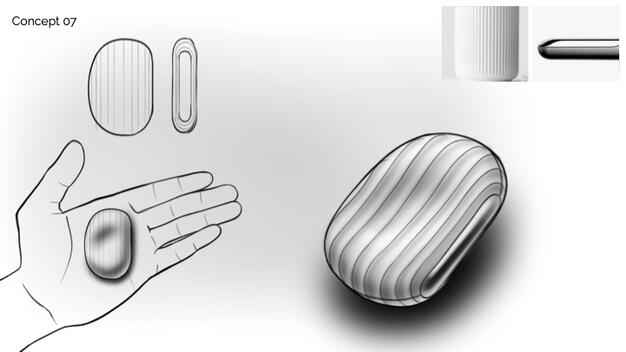

With that, we added an electrical engineer (Phil) and an industrial designer (Rotimi) to the team and started our development sprints.Rotimi would create concepts that Tyler and I would approve. I'd take the design and make it manufacturable. Meanwhile Phil would research the components to use and create a PCB that worked around our selected design.

Electrical Challenges Appear

Immediately, we ran into problems. Supply chain constraints haven't let up today, but were even worse when we got to work.Our original plan called for basing the product on either an ESP32 or nRF52840 based BLE module. These are common components, but at the time, lead times were over a year.Phil's alternatives wound up including the Sparkfun Artemis board. While it was a new product, it was in stock, FCC certified, and Arduino compatible.We would end up mitigating many other supply chain issues, but this was one we needed to get right in the beginning.Initially, we also wanted a Qi-based charger. The costs of these components turned out to be too much, causing us to switch to pogo pins.

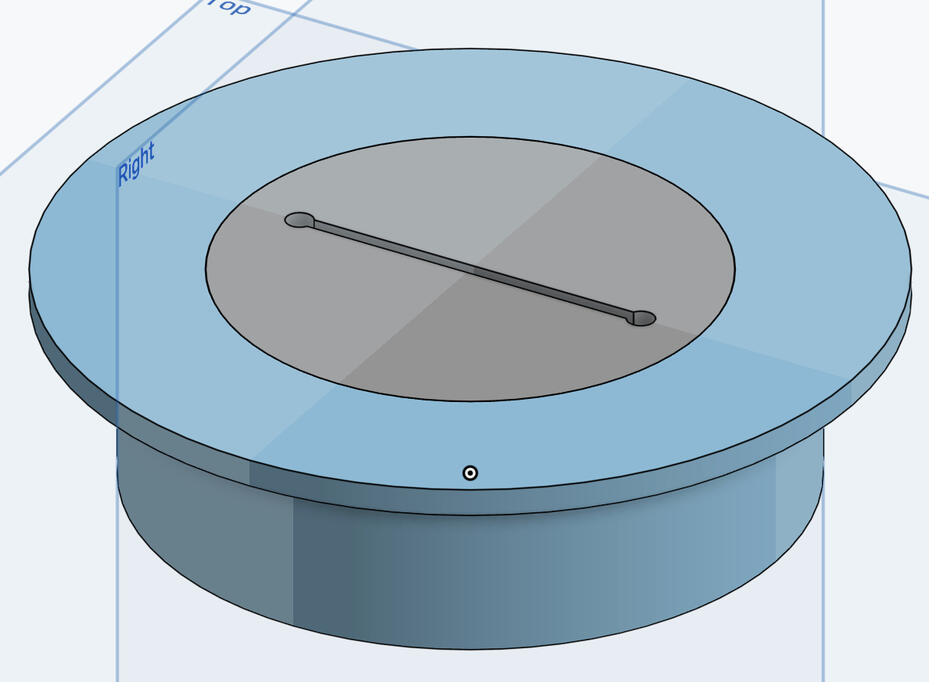

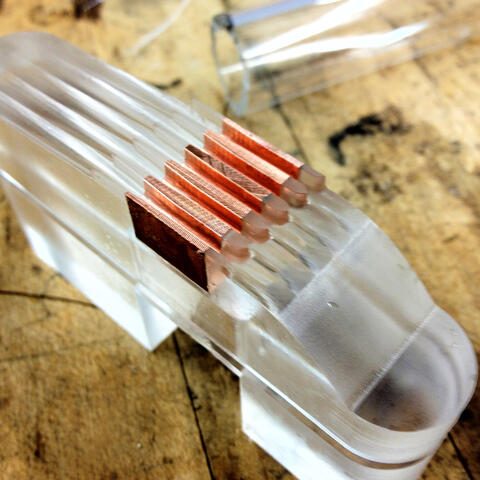

Vibration Testing

Phil started looking for available LRAs while I created a testbed.The advantage of an LRA over another vibrating motor is that it can provide alternative sensation patterns. While it can simply vibrate, can also make a single "tap", a series of taps, heartbeat patterns, rising and falling sensations, among virtually any other patterns.We believed that this would be another feature to separate us from our competitors, and I tested these patterns alongside our therapy advisor (AJ).Meanwhile, Phil completed his research, and we selected a Vybronics VG1040003D.With the major components selected, we got to work on design.

Industrial Designs

Rotimi created dozens of hand-drawn and rendered concepts along with CMF (color, material, finish) strategies that incorporated both tech and nature.While they were all great, we weren't quite in love, and did go back to the drawing board.

We wound up falling in love with this general shape. The question was, how do we light it up?Concept D was too tempting to ignore, which is why we chose it. Unfortunately, Concept D wound up being an order of magnitude more difficult than any of the others. It required too many LEDs, and diffusing the light was a challenge. See "Lighting Goes Wrong", below.But we had a concept. Onwards!

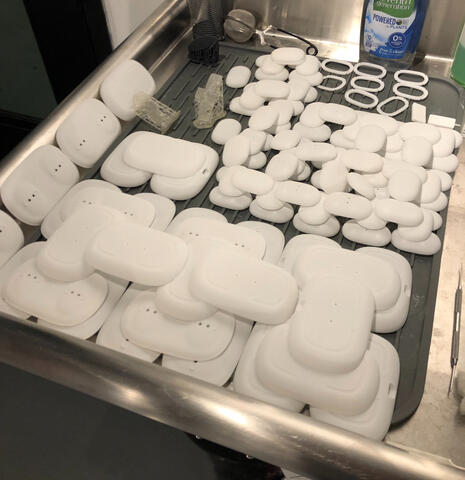

Prototypes

We created a series of functional and aesthetic prototypes to share with customers, manufacturers, and investors and to test lighting.Aesthetic prototypes were made through Honpe. I made the functional prototype housings at Newlab on SLS 3D printers.Eventually, the functional prototypes were used in-session with therapists and clients.

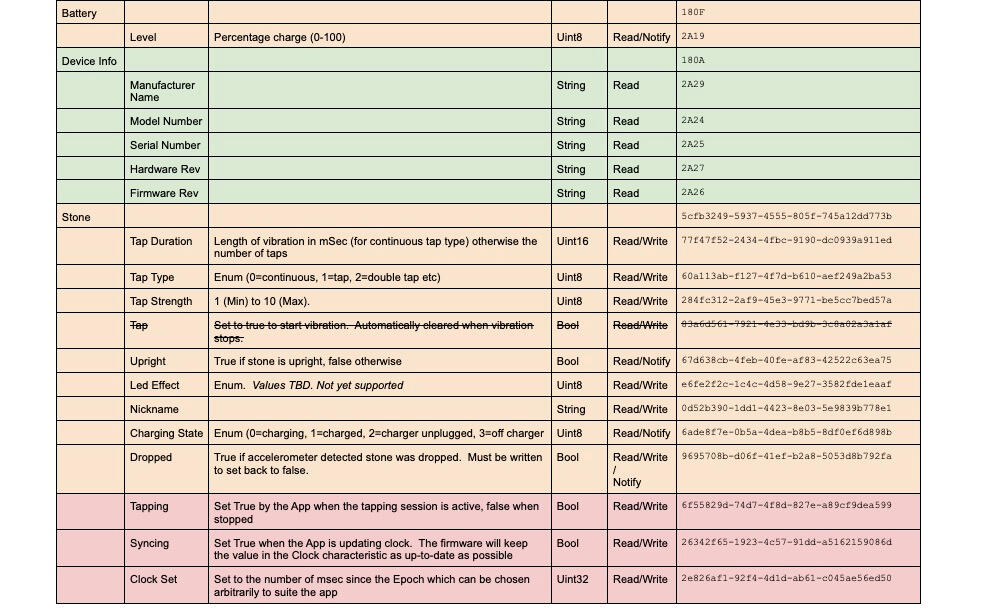

Firmware

Phil's Firmware was coming together well enough that he built a "Bluetooth Services" document.This material acted as an API for the software team to use. The app could make calls to the services in the list to turn on stimuli, alter settings, and diagnose errors.An unusual challenge for this device was keeping track of time. Every time a user sent a new command (to stop, start, or change the speed or intensity), the Sparkfun Artemis clocks resynchronized.However, if adjustments weren't made, they would eventually desynchronize. A vibration to the left hand might overlap with a vibration to the right, for example.We determined that overlap of up to 100ms was acceptable, but any more than that was distracting from the therapy.Since a marathon therapy session might not involve any adjustments, we needed a way to stay synchronized. Using the iPhone app to constantly send signals wasn't ideal and wasted battery life.Instead, the Sero Stones had to periodically talk to one another and to the iPhone app, ensuring that they stayed synchronized.

Vibration Goes Wrong

One thing we should have noticed earlier was vibration strength.Our early testing showed the LRA produced the vibration we required, but as we got further along, something was wrong. The strength was roughly 75% of what we needed it to be.After some research, we learned that the LRA and its driver were calibrated to a much larger mass (100g). Our previous tests had been on a heavier platform. Sero Stones were 15g, so we had a few options for fixing this:

Increase the mass of Sero Stones

Rewrite the libraries for the LRA driver

Find a different LRA driver

Swap out the LRA for a vibrating motor

We initially tried increasing the mass through lead putty. The weight still wasn't nearly enough and the putty absorbed more vibrations.Rotimi briefly looked into increasing the size of the Sero Stones, but meaningful increases in mass required a device that was too big.Having Phil rewrite the drivers would take months. Finding a new driver would also take time and was especially tough with the component shortages.In the end, we needed to switch to a vibrating motor (and a new driver) and found one with the same volume as the LRA (also from Vybronics). While the additional stimuli patterns were tempting, they were a nice-to-have. Writing Firmware for the motor did push us further behind, but not as much as the other options would have.

Lighting Goes Wrong

Our plan for lighting up the Sero Stone housing turned into a mess. The intended effect was for the Sero Stones to appear as a solid piece when off, but allow light to "crawl" up the sides when lit up.This was relatively easy for a prototype shop to do, but much more difficult in production.The design called for the bottom half to be opaque and coated in a clear, soft-touch polyurethane. Easy enough.The top was more complex.

In the above image, the housing is made of transparent ABS.The grey area would be coated in a clear, soft touch polyurethane. The black would be black paint or an overmold. Orange was clear and uncoated, but would attach to the bottom half of the housing.The lighting was to go through the blue area, which was to remain uncoated, and be diffused by the housing and coating.Looking back, we should not have fallen in love with this design. In my mind (and coming from a coatings background), we would be able to mask the areas properly.We received several "Decline to Quote" responses from coating houses. Others came back with absurd unit pricing. It was enough to consider a redesign.

Enter in-mold films:

These films were printed with tiny dots that appeared to go from opaque to clear, depending on their distance from one another. They also had soft-touch properties.After printing, the films were shaped to fit an injection mold, and bonded to the molded plastic.Problem solved.

The Supply Chain and DFM

As we got closer to finishing the product, we started figuring out how we'd actually make the product and who would do it for us.Our small quantities and the recent supply chain issues had us lean towards North American manufacturing.PCBs would be made outside of Toronto and Injection Molding and assembly on Long Island.We'd hoped to attach the Sero Stone and Charger housings together using ultrasonic welding. However, the coatings and films we'd covered the product were too soft, absorbing the energy of the ultrasonic welder.Instead, we designed notches into the Sero Stone housings for cyanoacrylate glue. The charger was redesigned with snap-fits.I added standard ribs and drafts to ensure that plastic molded properly.Glue (already present on the surface) kept the motor in place initially, pressure from the PCB locked it in place. Heat staking secured the PCB. The magnets were pressure fit and then held in place with glue.

The Demo

Sero App

Contents

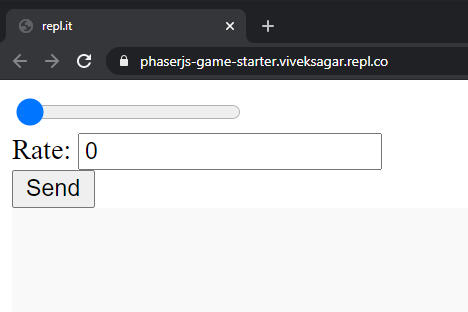

Sero App Proof of Concept:

The first proof of concept was built on Unity and it wasn't pretty (special thanks to Vivek Vidyasagaran!), but it was just enough. It was stuck in a desktop web browser, but it worked remotely. The weekend it was built was the first time tactile EMDR was practiced over the internet.

App technical, UI, and UX requirements

For our first 3D printed devices, we needed something more elegant. It needed these features, at minimum:

iOS support

Bluetooth LE support

The ability to turn on and synchronize two Bluetooth devices

Useable for in-person and telehealth EMDR

Control over both speed and intensity of motor vibrations

HIPAA Compliance

The connections needed to look like this:

And the UX steps needed to look like this:

Session UX:

In Person Session:

Therapist Opens App

Therapist Switches on Sero Stones

Therapist hands Sero Stones to client

Therapist selects "In Person Session"

Therapist selects their Sero Stones to connect to over Bluetooth

Therapist starts appointment, controlling speed and intensity of Sero Stones with a slider

Therapist ends appointment and Sero Stone session.

Remote Session:

Client and Therapist are speaking over telehealth platform of their choice (e.g. Zoom)

Therapist and Client Open Sero App

Client Switches on Sero Stones

Therapist and client select "Remote Session"

Client receives a random code

Client tells Therapist this code over telehealth platform

Therapist enters code

Therapist is connected to Client's app

Client selects their Sero Stones to connect to over Bluetooth

Therapist starts appointment, controlling speed and intensity of Sero Stones with a slider

Therapist ends appointment and Sero Stone session.

Sero App v1.0

Again, Vivek came through. He built an app based on React Native and Firebase that did just enough to test the devices:

This app was used for thousands of EMDR sessions with the prototype devices seen on this page. While not perfect, it was just good enough.

Lessons Learned, Limitations of React Native, and New Requirements

The v1.0 app was great for learning. The most critical lesson we learned was that building on top of React Native wasn't going to work long-term.Apple (and Android) place heavy restrictions on Bluetooth. Using React, if the phone went to sleep, Sero Stones disconnected. If the user put the app in the background, Sero Stones disconnected. Sometimes they disconnected after a long period of time. When disconnected, Sero Stones just stopped working.Staying connected is critical when a product is used for sensitive therapies. If a client was dissociating and lost connection, they could be in trouble.Most telehealth users had two devices: they spoke to their therapist on a laptop and connected to Sero Stones on their iPhone. That said, many users wanted to use both the Sero app and Zoom on their phone at the same time. With React, this was impossible.Building in React Native had advantages (speed, easy porting to Android), but we made the decision to switch to Swift and add a few additional requirements:

New App Requirements

On HIPAA Compliance

The v1.0 app was intrinsically HIPAA compliant. Users did not log in and no patient health information was stored.Since the new production app needed to include user accounts, we needed to be more careful. Our Firebase backend was sufficient for this requirement.While email addresses of clients were collected, they were not stored in a way we could read and they were not sent outside of the app.

Building the Native Production App

We couldn't build the iOS app on our own (or with Vivek's help), but raised money and hired iOS engineers. Our existing Firebase backend was sufficient for this version.UX and connections broadly stayed the same.The project took advantage of Agile methodologies and regular sprint plans with software, design, and electrical engineering teams for synchronization.

While still not perfect, the app is close and improving as we go.Bluetooth control to two devices in particular will always be a challenge. Synchronizing the clocks of the Sero Stones requires specialized firmware and app relationships.Our partners are testing the devices with their clients and recording quantitative and qualitative feedback which we're using to make the app better.

Check out the demo here:

Sero Beta

Contents

Why Sero Beta?Hardware is hard. Even if you've done it before.In Spring 2022, Sero Stone production was pushed back again. Our customers were still holding out for their devices, so we needed a stopgap.Could we build a HIPAA compliant web-app that used off-the-shelf devices?

We needed to find devices that met these constraints:

Vibrating

Handheld

<$100

Bluetooth enabled

Capable of working as a pair

We explored using two smartwatches, two smartphones, and bluetooth toothbrushes, but nothing worked cheaply and quickly.

Joy-Cons

That is, until we saw people playing Mario Kart. The Nintendo Joy-Con controllers are held in each hand, are available at any Best Buy, vibrate, and work with MacOS and Windows. Exactly what we needed.

Sero Beta is Born

We quickly hired an intern (Spencer) and set up a project. Tyler would handle design, the intern would build (in React and our existing Firebase backend), and I would manage the project and communicate with stakeholders.In the beginning, we needed their qualitative information to build a roadmap. This was acquired through emails, surveys, town halls, and focus groups. After launch, we used additional quantitative data from surveys and usage analytics to prioritize features.

Sero Beta UX:

In Person Session:

Therapist opens website at https://sero.health

Therapist signs in

Therapist Switches on Joy-Cons

Therapist hands Joy-Cons to client

Therapist selects "Quick Session"

Therapist pairs Joy-Cons to their computer via Bluetooth

Therapist pairs Joy-Cons to Sero Beta

Therapist starts appointment, controlling speed and intensity of Joy-Cons with sliders

Therapist ends appointment and Sero Beta session.

Remote Session:

Client and Therapist are speaking over telehealth platform of their choice (e.g. Zoom)

Therapist and Client open website at https://sero.health

Client Switches on Joy-Cons

Therapist and selects the client from their dashboard

Client receives a notification to join the session

Client accepts request

Therapist is connected to Client's browser

Client pairs Joy-Cons to their computer via Bluetooth

Client pairs Joy-Cons to Sero Beta

Therapist starts appointment, controlling speed and intensity of Joy-Cons with sliders

Therapist ends appointment and Sero Beta session.

Within two weeks, we had a beta version for our users. Over time we added user accounts, more granular control, and additional EMDR features. It's consistently grown at 20% WoW.

Staying HIPAA Compliant

Our original smartphone app was intrinsically HIPAA compliant. Users did not log in and no patient health information was stored.The Sero Beta app needed to include user accounts, so we needed to be more careful. Our Firebase backend was sufficient for this requirement.While email addresses of clients were collected, they were not stored in a way we could read and they were not sent outside of the app.

Do we need Sero Stones if Sero Beta works?

Could we have abandoned Sero Stones and focused on Sero Beta? Maybe. Many therapists were happy with the ease-of-entry and kid-friendliness. On the other hand, many therapists felt that they wouldn't be taken seriously if they gave their clients game controllers. Sero Stones were still critical.

Check out the demo below:

Building Sero

Contents

Sero Research

Since we weren't therapists or neuroscientists, we had to develop deep user expertise as we went.The first few weeks of Sero's existence were spent interviewing dozens of therapists (and eventually hundreds). We needed to understand how they practiced EMDR, how they learned about EMDR, what was missing from their existing tappers, how they decided on their tappers, and if there was even a good problem to solve.Along the way, we had to learn about the therapy itself, why it works, why it is superior to other therapies in certain situations, and the competitive landscape. My synthesis of this info can be found here.Our line of questioning was derived from The Mom Test, a book on asking good questions from customers. Main points boil down to:

Don't pitch your ideas to customers.

Learn facts. Dig and ask more questions till you have exact facts and data.

Don't mention your solution.

Don't listen to opinions, collect facts and pain points instead.

Compliments means nothing. Really nothing. Deflect them and dig deeper.

You can’t learn anything useful unless you’re willing to spend a few minutes shutting up.

If you don’t know what happens next after a product or sales meeting, the meeting was pointless.

Until you’ve got a working business model and a repeatable sales or marketing process, the founders need to be in the meetings themselves.

Sero Positioning

With information from dozens of therapists, we knew that there was a gap in the EMDR equipment market.

There was no clinic-facing tactile EMDR hardware that could be used remotely.We settled on making non-threatening EMDR devices that would be sold to therapists and their clients.Unlike other mental health devices, these would not sell directly to clients without their therapist's permission. Mental health devices already face a great deal of skepticism, which we wanted to avoid.

Sero KPIs

We considered our customers to be therapists (and not their clients).A therapist will see 20 - 100 therapists in a given year. By bringing therapists onto the platform, we believed that we would be able to acquire a meaningful percentage of this number to the platform as well.To that end, our KPI became "Sales to Therapists".When Sero Beta launched, we added "Therapists on Platform". Secondarily, we paid attention to Net Promotor Score.

Product Requirements

Hardware

| Requirement | Reason |

|---|---|

| Entirely wireless during use | Tangled, short cables were problematic |

| Remote capable | Therapists and clients were not often in the same room |

| Five hours of battery life | Marathon sessions are not uncommon |

| Easily graspable by a child | Devices were used by people of all ages |

| Integrated lights for visual stimulus | Combining stimuli provided certain clients with enhanced therapy |

| Vibration strength must be on par with existing products. | Therapists had become accustomed to certain sensations. |

| A Linear Resonating Actuator (LRA) instead of a vibrating motor | To create new tactile stimuli |

| Consolidated, custom PCBs | To reduce the size of the product |

| Charging pad with magnetic placement | To eliminate USB cables |

| Battery life reported to app | To understand when power was low |

| "Sleep Mode" | To eliminate the need for a power switch |

| Distinctive, soothing appearance inspired by nature | Competing devices used confusing designs |

| Support for Over-the-Air Firmware updates | We would want to fix the product without plugging it in |

| Washable with standard cleaning products | Therapy offices might have dozens of clients who might not wash their hands. |

Software

| Requirement | Reason |

|---|---|

| iOS support | Our limited resources meant developing for a single platform |

| Bluetooth Low Energy (BLE) support | The device was to be wireless, and BLE was the standard |

| Built natively in Swift | To work around Bluetooth restrictions present in platforms like React |

| Operable in the background or when the iPhone was asleep | Some clients wanted to receive tele-therapy on their phone while the therapist controlled their Sero Stones. They needed to stay connected regardless. |

| The ability to turn on and synchronize two Bluetooth devices | We had settled on building two separate, wireless devices, rather than physically connected ones |

| Useable for in-person and telehealth EMDR | Therapists wanted the option to practice wherever they were |

| Control over both speed and intensity of motor vibrations | Stimulus level changes throughout the session |

| HIPAA Compliance | Federal regulatory requirements |

| User accounts | To save user's settings |

| Battery life indications | To indicate if the device had power for another appointment |

| Integrated sounds | For additional stimulus options |

| Capable of pushing out Over-the-Air Firmware updates | For Sero Stone fixes and updates without plugging them in |

Pre-Sale Process

To prove traction for investors, we held a pre-sale for Sero Stones while they were in development.We built initial interest through a waitlist through EMDR Facebook groups, a podcast, and word of mouth.In time, we amassed a list of more than 1,700 EMDR therapists. This represents over 5% of the EMDR therapists in the world (from total number provided by EMDRIA, the EMDR interest group).From this list, we sold $100k worth of devices at full retail price. We A/B tested pricing to determine that $349/unit was the correct cost for individual devices.

Sero Future Sales Strategy

From our research, we understood that therapists needed to be trained by an EMDRIA-allied group in the USA/Canada (or the local EMDR body in their country) in order to offer EMDR.Trainings typically started with a course over two weeks, but additional certification was recommended (and yearly Continuing Education was required). Therapists learned about the tools available, like EMDR platforms, at their trainings and CE courses.EMDR trainers typically lead a course 4 - 6 times per year, and have 20 therapists in a course.Our plan was to acquire newly trained EMDR therapists at these courses. We would partner with EMDR trainers and provide sales assets to make sure they had all the information they needed.For existing EMDR therapists, we planned to build a CE course specifically for Sero hardware. This would count as their requirement, and could be free.In both cases, the expectation was that Sero would be trusted hardware for remote EMDR. This connection with therapists would allow them to promote our products to their clients.

Universities and Partners

We've often heard people ask "Why don't you work with the military or the VA?"It's more difficult than just selling to the government. For small companies, the easiest way in is through Small Business Innovation Research (SBIR) or Small Business Technology Transfer (STTR) programs.These programs allow small businesses to perform R&D and eventually gain government contracts.In order to validate our product even more and make a better case for these programs, we developed academic partnerships. In particular, we worked with The Trauma and Stress Research Consortium (TSRC).This group is based out of The Kinsey Institute at Indiana University.We specifically worked with Dr. Gregory Lewis, a Professor of Intelligent Systems Engineering, who applies sensors and methods quantify the interaction between trauma, physiological and behavioral regulation, social functioning, and mental wellbeing.While creating our proposals, we also had a chance to work with Dr. Steven Porges, the developer of Polyvagal Theory, a popular construct in physiological regulation.Our first grant application was through Defense Health's Traumatic Brain Injury and

Psychological Health Research Program (TBIPHRP)

On Building a "Medical Device" vs. "Wellness Device"

Offering Sero Stones for free to clients was an enticing idea. Our options for doing so boiled down to:

Becoming eligible for insurance reimbursement

Becoming part of an Employee Benefit Program

We pursued option two because option one had certain regulatory requirements.While there were exceptions, Sero Stones would likely need to be an FDA Class II medical device. These devices are "A medical device with a moderate to high risk that requires special controls."The benefit to being a Class II device is that you can make specific claims about what your product does. In Sero's case, we could say things like "Sero Stones treat PTSD". Without this designation, we could not make real claims.Unfortunately, getting to this level requires clinical testing that we did not have the time or resources for.Instead, we pursued limiting ourselves to being a "wellness device" for the time being. We could make no claims about ourselves and move the onus of effectiveness onto the therapists. Mentioning EMDR was OK, but diagnosed conditions were not.While not ideal, this enabled us to move quickly and did not box us in. Once development of Sero Stones v1.0 was complete and we were on steady ground, we could pursue FDA clearance.

Where Sero Could Go in the Future

The Sero Clinic

Potential clients often reach out to Sero for help finding a therapist. There appears to be value in vertically integrating the service, employing therapists directly, and creating a trauma-focused virtual therapy clinic. We spent significant time exploring the requirements for launching a virtual clinic in California.EMDR and Psychedelics

There is evidence that EMDR and Psychedelics benefit one another.EMDRIA, the leading body of EMDR experts, teaches a course on integrating them.Sero App Content

We believe that customers will pay $10 - $20 per month for access to Sero content and features. These may include:

Exercises recorded by their therapist

A library of mindfulness content synchronized to Sero Stones

Therapy progress tracking

Medical Device Designation and Insurance Reimbursement

$349 is a price that many clients appear willing to bear, but is too expensive for others. Insurance reimbursement is one way to reduce this burden. The path to insurance reimbursement includes these steps:

Development of Standard Operating Procedures for Assembly and Use of Sero Stones

Successful Clinical Trial showing reduction in PTSD symptoms

Class II Medical Device Designation

Negotiation with Insurers

EMDR and Biofeedback

Trauma recovery is measured using a scale of Subjective Units of Distress (SUDs), which is, of course, subjective and prone to error.There may be more value in listening to the body to determine how effective treatment is. Sensors that measure Electrodermal Activity (EDA) and Heart Rate Variability (HRV) are well respected, can be embedded in future Sero Stones and possibly used to track treatment progress.One challenge to switching from SUDs to objective measures is that insurance companies already work around SUDs. In time (and with their partnership), fixing this could be on the table.Even if insurers never adjust to objective measures, there is is still value in pursuing them. Future Sero Stones may also be able to adjust the speed and intensity of Bilateral Stimulation autonomously based on these sensor readings, reducing the burden on therapists.

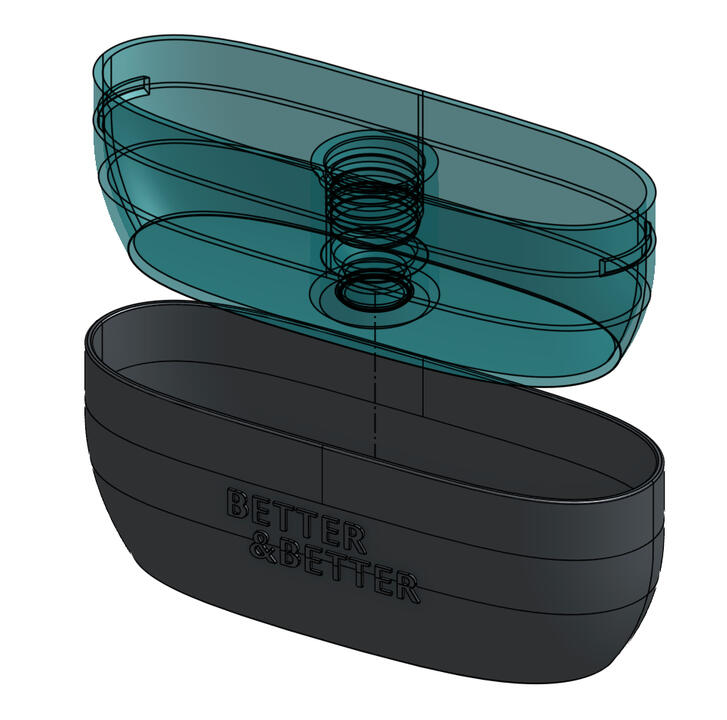

Better & Better

D2C, Eco-friendly Oral Care Products

VP, Engineering

Contents

Accomplishments

Developed toothpaste tubes with 45% less material (and 84% less volume) than traditional tubes.

Invented a novel "Toothpaste Dispenser System".

Skills Used

Project Management

Onshape/CAD

BaseCamp

GD&T

DFM/DFA

Supply Chain Management

About Better & Better

Better and Better was founded by the creators of Meural. After a year at Netgear, they were ready for a new challenge, and asked me to come along.The main thread of Better & Better was to create a razor-and-blades subscription model for better toothpaste.This had been done in razors (of course), deodorants, and any number of up-and-coming D2C brands. It just hadn't been done in toothpaste yet.The original idea was to create an automated toothpaste dispenser ("a robot for the bathroom"). This device would dispense an ideal amount of toothpaste to whoever was using it at the time.Very quickly, that switched to a focus on eco-friendliness and health. Instead of normal toothpaste, we wanted to add ingredients that made an oral hygiene practice even healthier (like vitamins) and remove irritants. These would be shipped on whatever your ideal cadence was.We launched a toothpaste dispenser, created toothpastes, and attempted additional accessories (flosses, toothbrushes).

My Responsibilities

Build initial proof of concept

Hire design and engineering team

Oversee development of Toothpaste Dispenser System and accessories

Oversee supply chain

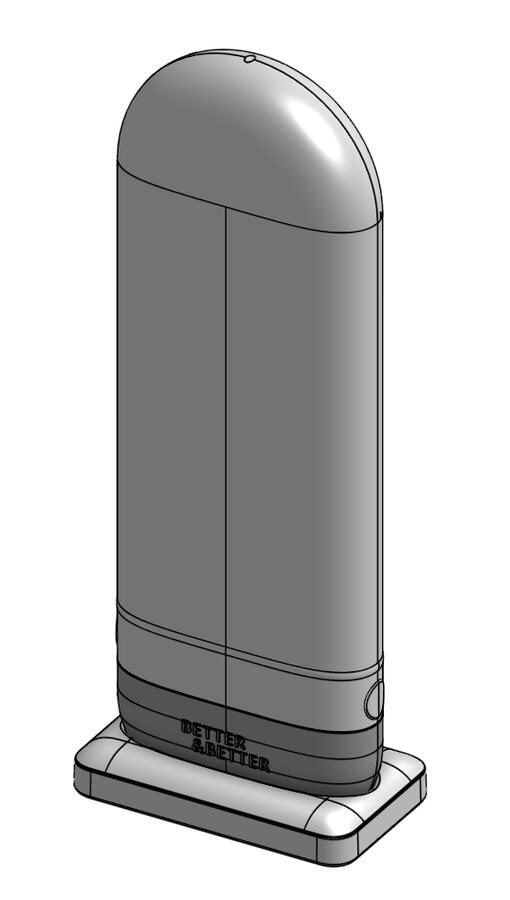

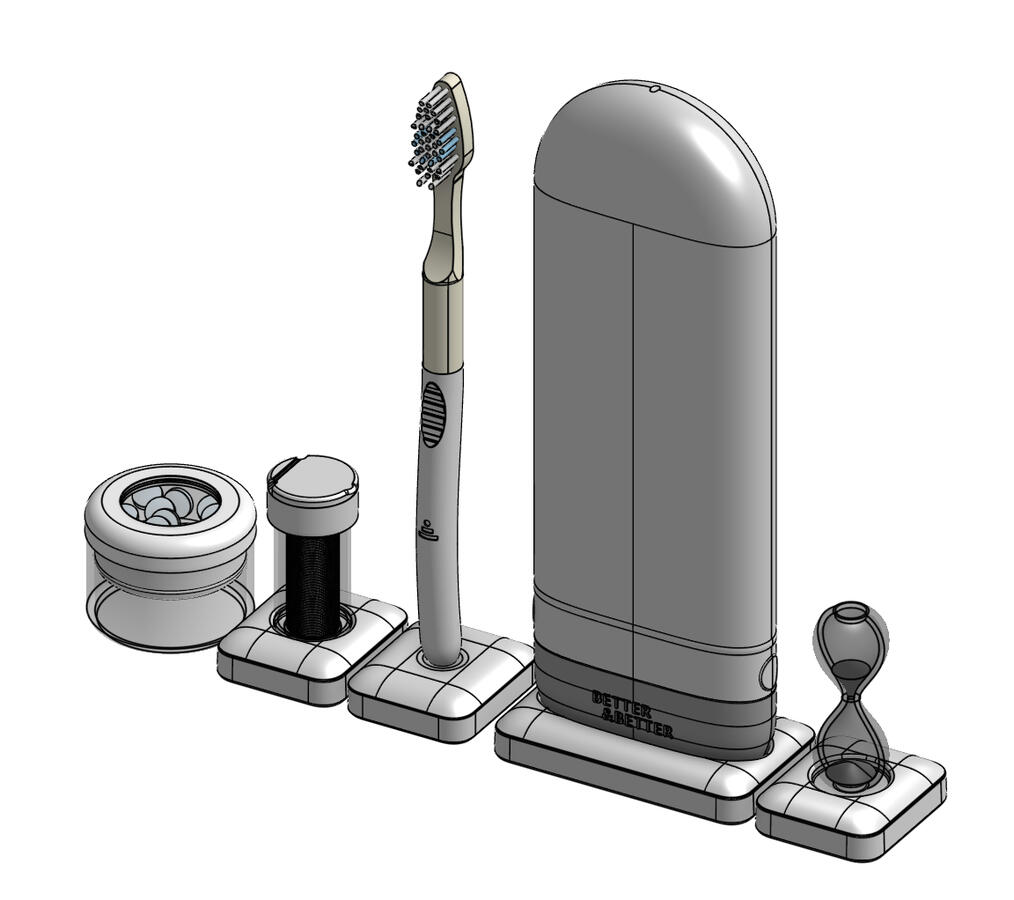

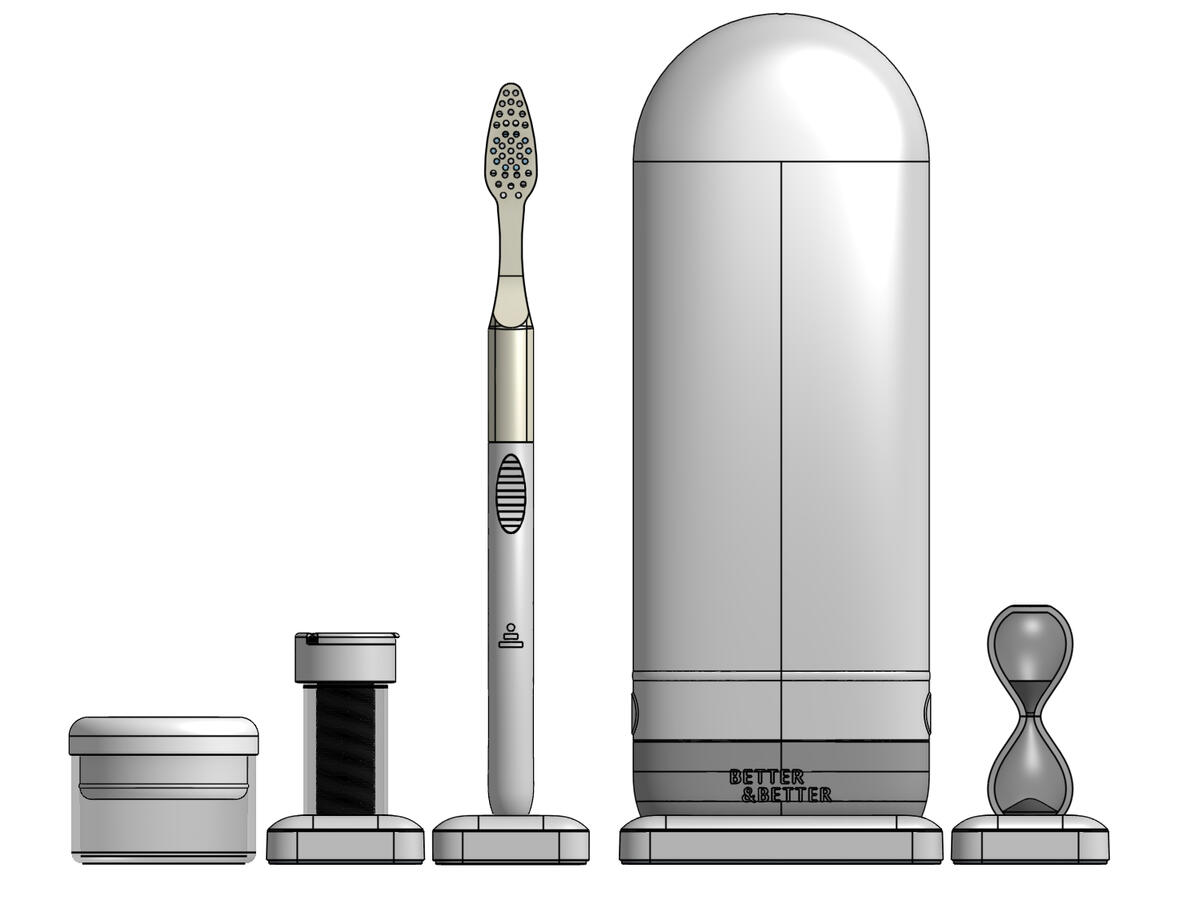

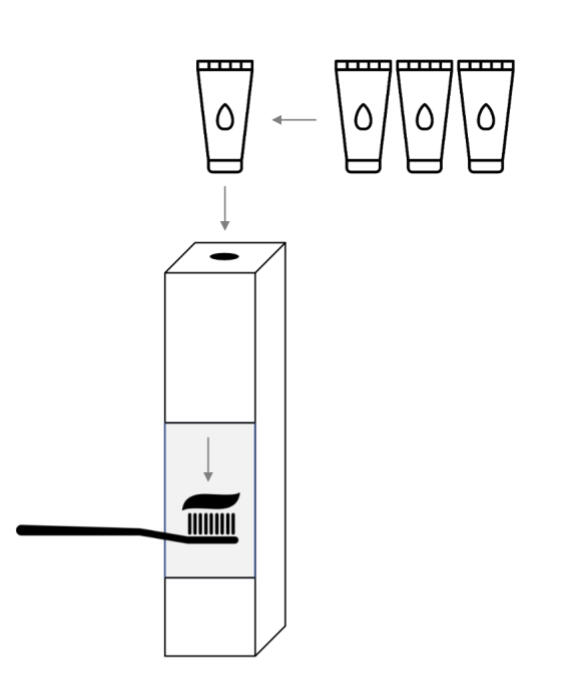

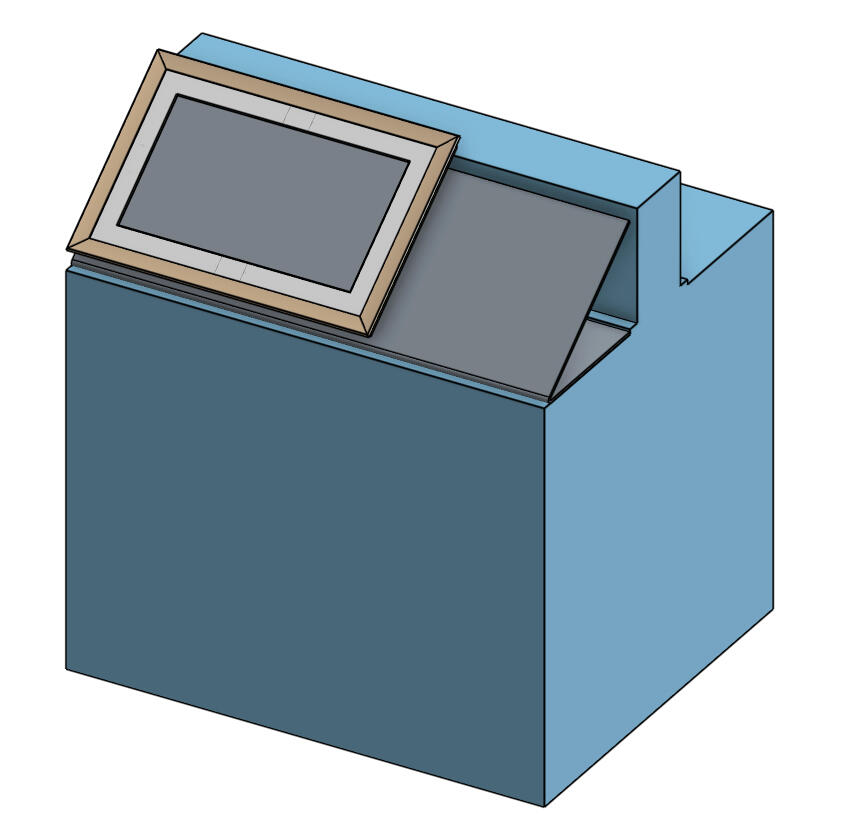

The "Toothpaste Dispenser System"

Part 1: The "Robot"

The initial brief for a "Toothpaste Dispensing Robot" was simple enough:

This proof of concept was just going to be used for the pitch deck.We needed a machine that accepted a tube of toothpaste and would automatically dispense toothpaste

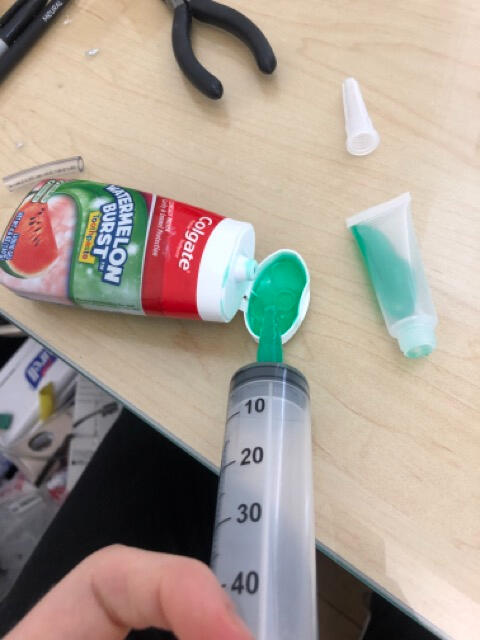

This monstrosity was designed in Onshape and printed by Shapeways.

Instead of building a pumping system with infrared sensors from scratch, I used an off-the-shelf automatic hand-soap dispenser, hacked it apart with a Dremel, and installed tubing that would accept a toothpaste tube.

The confined space of the prototype meant that it could only accept travel-sized tubes of toothpaste.One fun detail we discovered early on is that toothpaste is viscous. Pumping toothpaste is far harder than pumping soap. For the prototype, this meant that we could only use toothpastes that incorporate mouthwash, since they're more watery than normal toothpaste.Unfortunately, these better toothpastes don't come in travel sizes, so I would fill syringes with ideal toothpastes and transfer the paste to small tubes.

Did it work? Sure. The company raised a pre-seed round of funding, and we moved on to a real dispenser.

Part 2: Airless Pumps and New Designs

After closing the initial funding, Better & Better changed strategies.Gone was the "bathroom robot" that enabled a "razor and blades" model for toothpaste.Instead, they wanted to make eco-friendly oral care products (so, no electricity in the product) that boosted every day habits (so, sublingual vitamins in the toothpaste).With that, we had a team to recruit and product requirements ready to go. These requirements included:

A retail cost of $40 or less

Eco-friendly materials

Aesthetically complementary to any bathroom

Capable of dispensing a uniform amount of toothpaste

Capable of fitting on any bathroom sink

Integrated 2-minute timer

Not more difficult to use than a regular toothpaste tube

Our industrial designers came up with several concepts.

Initially, we fell in love with the idea of using an airless pump as the basis of the dispenser.These mechanisms are typically used in high-end cosmetics. Naturally, we thought that using one would give us a high-end feel.Unlike high-end moisturizers, we had two issues: 1) As we learned while making the initial proof-of-concept, toothpaste is really viscous. 2) We were trying to pump out ~1 cubic centimeter of toothpaste — way more than a typical moisturizer.These issues meant that we were dispensing inconsistent toothpaste amounts and it was too hard to pump.With enough time, we could have developed the system we really wanted. Unfortunately as a pre-seed startup, we needed something new.

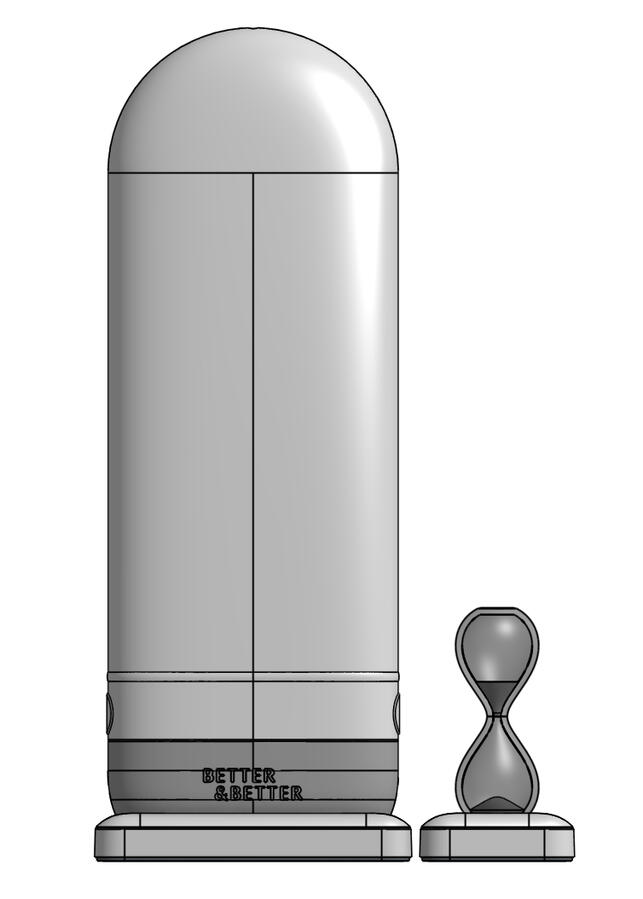

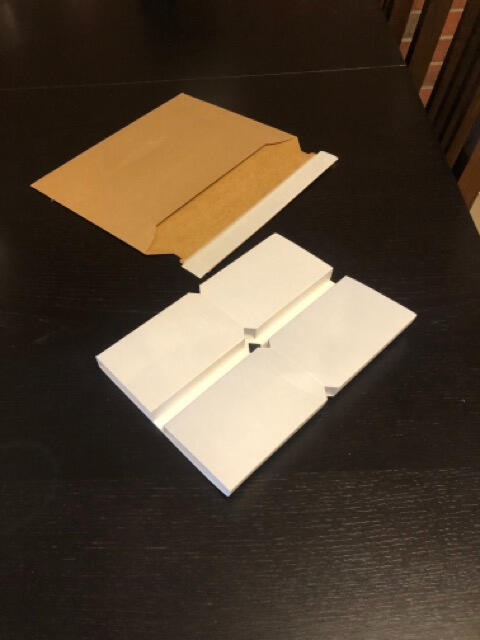

In the interest of speed, the industrial designers came up with a new concept: a refillable squeeze pouch. With only two major components, this would be simpler than building a pumping system. It also gave us ideas for the toothpaste tubes.

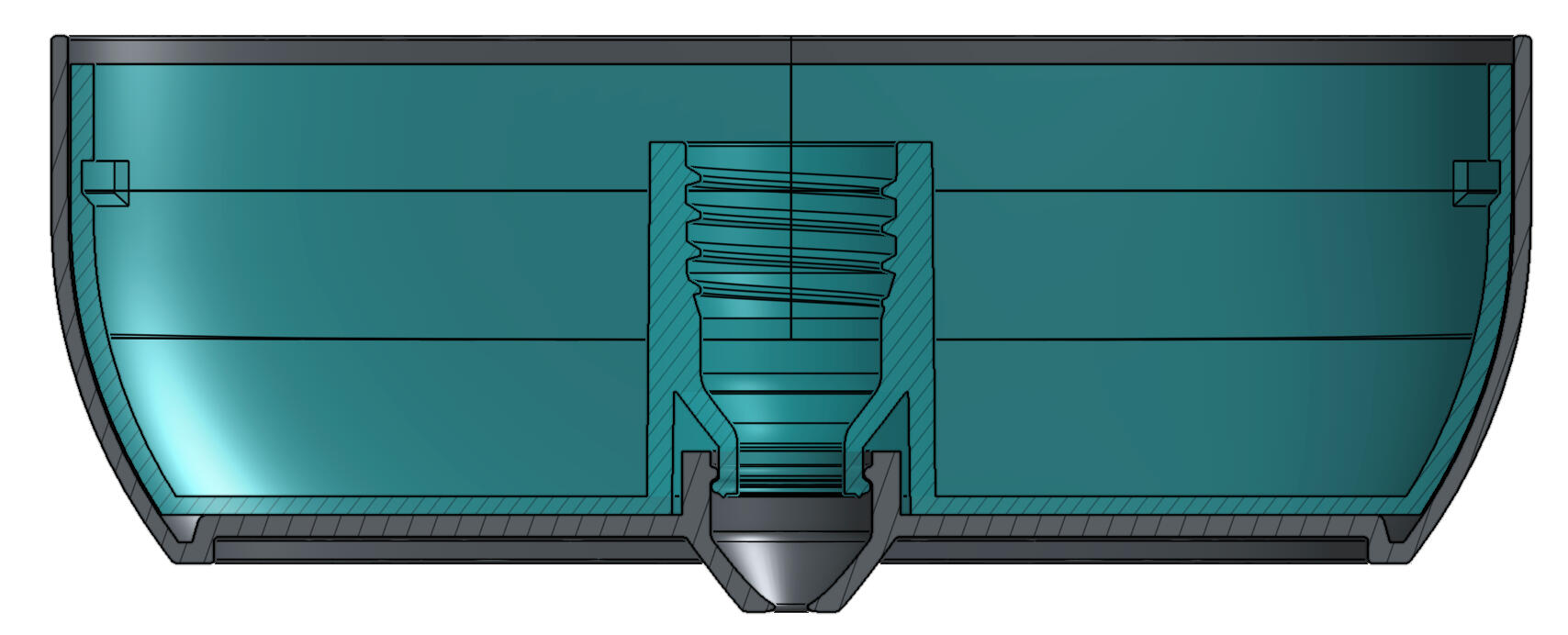

New Constraints and Toothpaste Tubes

The next steps of the design were constrained by two major points:

Integrating a timer into the design

An opportunity to use an obscure shipping method

2-Minute TimerInitially, we wanted an automatic timer that would start as soon as the toothpaste was placed back on the counter. Unfortunately, we didn't have the resources to design a timing movement from scratch, so we needed to source one from Alibaba.

This wound up being less than ideal. Timers are easy to wind, but harder to design into the dispenser system (winding would need to happen in a linear motion). They're also really loud.It was possible to configure the timers to run for a specific amount of time and to remove the obnoxious ring at the end. Unfortunately, removing the tick-tock sound is much harder. Linear winding with a rack-and-pinion mechanism was error-prone as well.Like the airless pump, we could have solved this issue with enough time. As a young startup, we didn't have that luxury.

With that, we stuck to a 2-minute hourglass (sourced on Alibaba). Far less than ideal, but as long as we had an elegant place for both the timer and the dispenser, we were all set.ShippingEarly on, we were given the constraint to make the toothpaste packages compatible with USPS Media Mail — Large Envelope Flat.This designation is typically used by USPS to ship magazines, books, videotapes (what?), and other non-advertising materials. The major advantage over other designations is that it's a flat fee to ship anywhere in the USA.In theory, as long as we kept below 1lb, we could ship for <$5. Packages were limited to 0.75" thick or less, so our toothpaste tubes needed to be even thinner than that.As we found out later, we weren't actually eligible to use this designation. This meant that our major constraint wasn't actually a constraint, but was a good north star for us.

We found a supplier of collapsable Media Mail envelopes that maximized our toothpaste tube thickness — we could go as high as 5/8".Typical tubes are have a capacity of 120ml. They pack this volume in tubes upwards of 1" in diameter. Constraining ourselves to 60% of the thickness would make for some interesting design choices.Toothpaste TubesThe team noticed that kids' juice pouches were ideal for holding fluids in a thin package. With the help of Cheer Pack, we determined the size and makeup of a non-gusseted toothpaste pouch with a window on the back to see how much toothpaste was left.Given the viscous nature of toothpaste, gravity doesn't have much of an effect. Even with the spout of the pouch pointing down, the toothpaste would not fall on it's own. While an interesting visual addition to the product this window was unnecessary.

In order to keep our 5/8" thickness constraint (and 120ml capacity requirement), the pouch ended up larger than expected, at 3" wide and nearly 7.9" tall (not including the spout).While large, the major benefit to this design was the lack of material. Compared to a typical toothpaste tube, we used ~half of the plastic and 33% of the volume.With that constraint managed, we had to adjust the size of the dispenser to match.

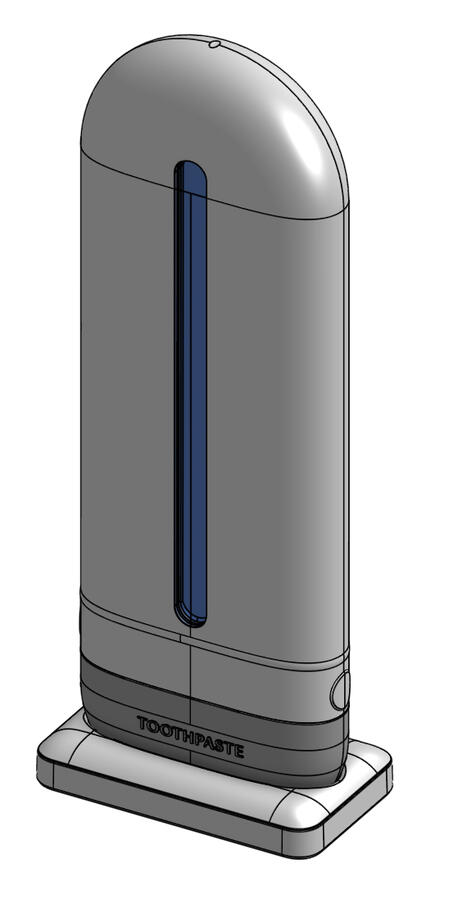

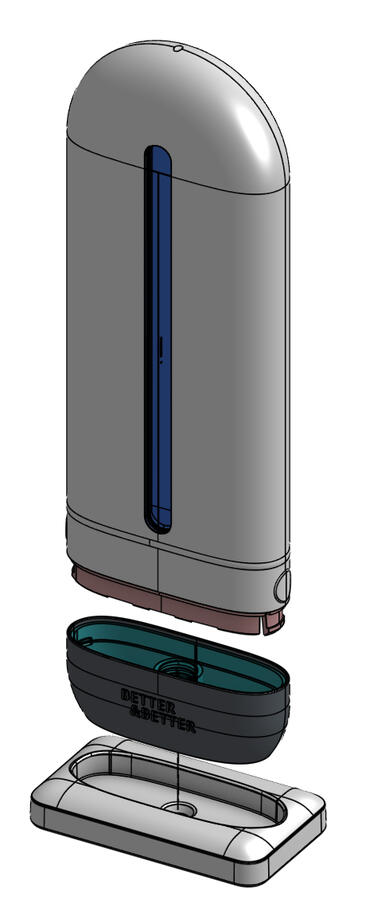

Final Design and DFM

Renders and CAD

Assemblies

The top piece of the dispenser involved three components: a soft, textured, white TPU squeezable portion, a clear, untextured TPU window, and a flexible Polypropylene ring. The ring was used to snap into the dispenser cap.Two overmolds were used for this piece.

The cap included two pieces (both ABS): an external metal plated cap for aesthetic purposes and an internal cap that contained fittings for the the pouch spout and to snap the soft portion of the dispenser. Caps were held together with a snap-fit.We had planned to include a valve in this section, held together by the two pieces. This valve did not add to the dispensing experience and was rejected from the final assembly.

The Stand was made up of two componts: an ABS main component and a TPU foot, which made use of an overmold.

Real Parts

We had the choice of USA-based or Chinese manufacturing for the dispenser.With several overmolded components, this was an ideal product for overseas production.Unfortunately, this was the early days of Covid and uncertainty was high. As a result, we stuck to USA-based manufacturers.The silver lining here was that we could mold "Made in the USA" into the device.

About the Toothpaste

Better and Better was not just about the dispener system. The toothpaste needed to be better as well. This was done in two ways: 1) Removing "bad" ingredients and replacing them with "better" ones. 2) Enhancing the toothpaste with vitamins and minerals that might be missing from the user's routine. Instead of taking supplements, you can just brush!

Removed "Bad" ingredients (apparently these are not uncommon):

Sulfates (specifically SLS)

Parabens

Artificial colors, flavors, preservatives

GMOs

Animal products

Plastic microbeads

Triclosan

Hydrated silica

Carrageenan

Gluten

Added "Good" ingredients, designations, and constraints:

Organic

Vegan

Environmental Working Group Verified

Coconut based

Vitamins B12, C, D3, E, and Zinc

Even though I was working on the product design and engineering, I still needed to be involved with toothpaste development. The updates to the ingredients had the potential to be far different from the toothpastes we were testing (specifically, viscosity).With that, I joined the team to camp out in Salt Lake City (the capital of contracted toothpaste development).

Other B&B Products

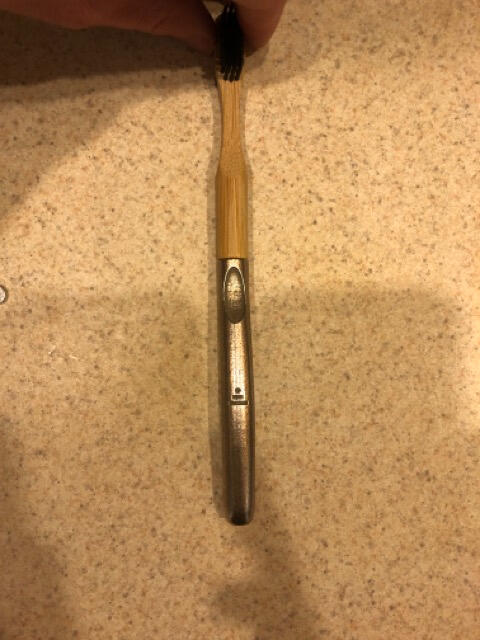

We created a number of other concepts at B&B. Unfortunately, I only have a few of them saved. Some include:

A metal/bamboo toothbrush

Floss and a floss dispenser

Mouthwash tablets and cup

The Toothbrush

Not satisfied with either environmentally-friendly bamboo or high-end toothbrushes, we opted to combine the two.The bamboo/brush portion of the toothbrush included a custom shape to match a competing brush from Oral-B.The "ergonomic handle" was made of die cast steel.The platform had the same proportions as the toothpaste dispenser. It was designed so that all pieces of the system (dispenser, timer, floss) fit together elegantly on the user's sink. The platform included magnets, allowing two toothbrushes to stand next to one another.This product remains unreleased.

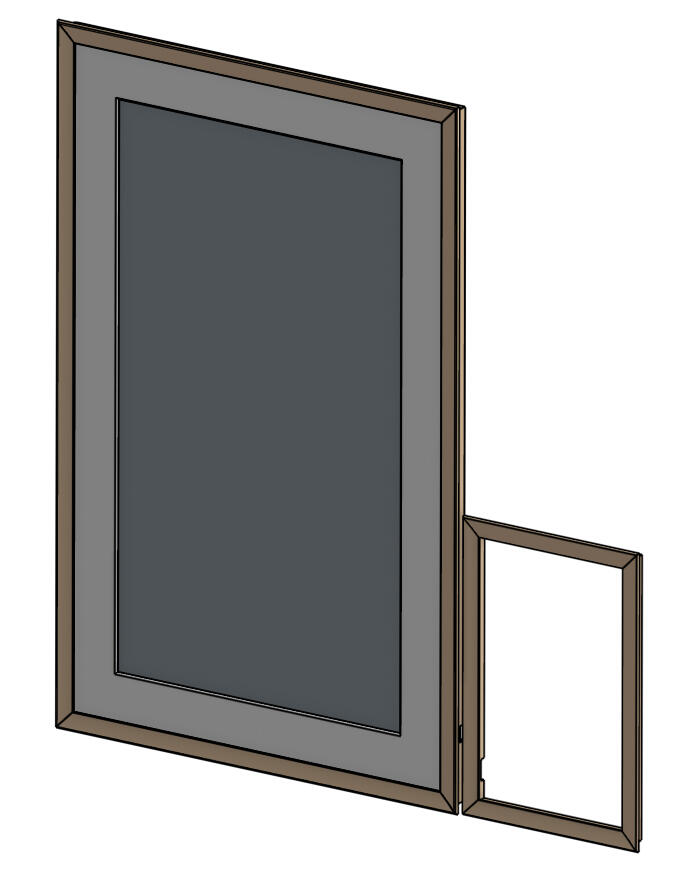

Meural (Now a part of netgear)

"Like a Kindle, but for Art"

Product Manager (at Meural)

Program Manager (at Netgear)

Contents

Accomplishments

Scaled flagship product by 10x pre-acquisition

Scaled flagship product 10x again, post-acquisition

Completed 3 generations of flagship

Reduced COGS by 50%

Expanded into accessories

Skills Used

Product Management

Onshape/CAD

GD&T

DFM/DFA

Supply Chain Management

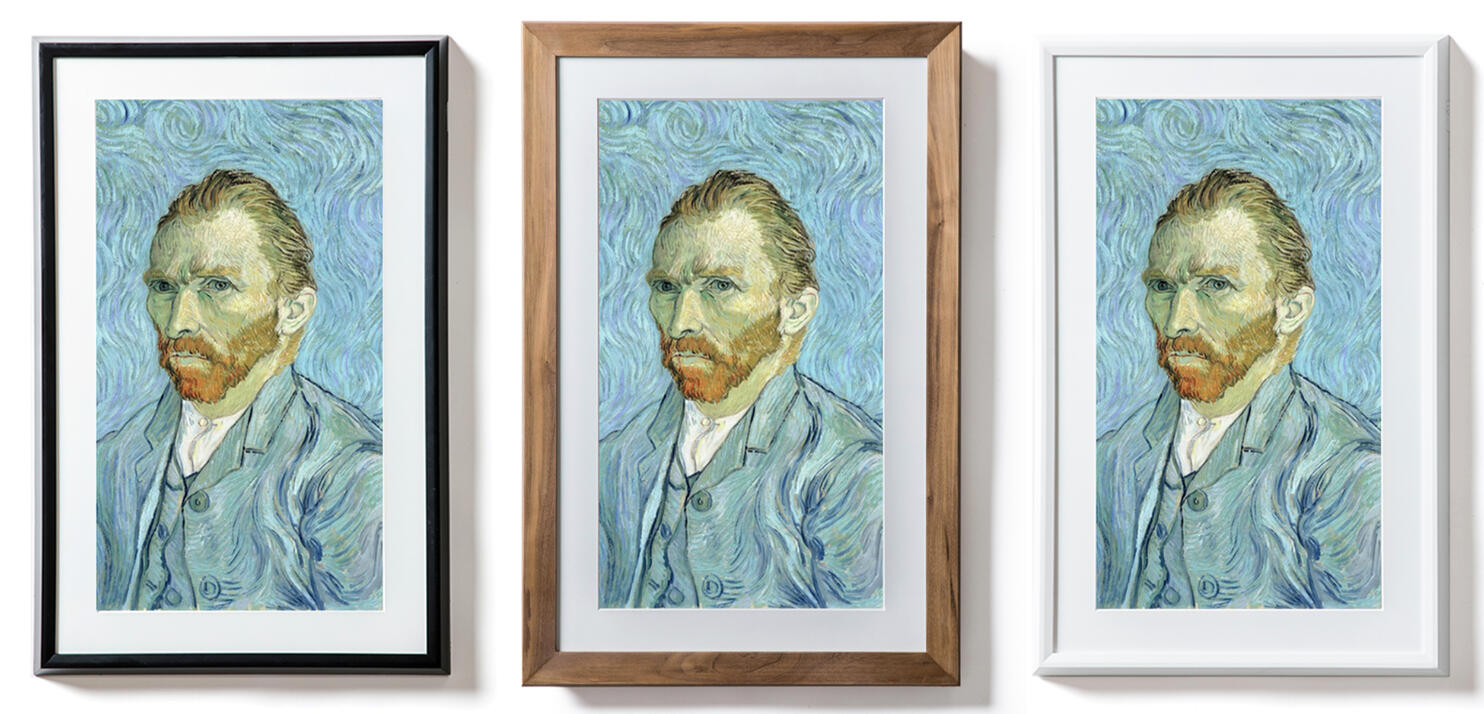

About Meural

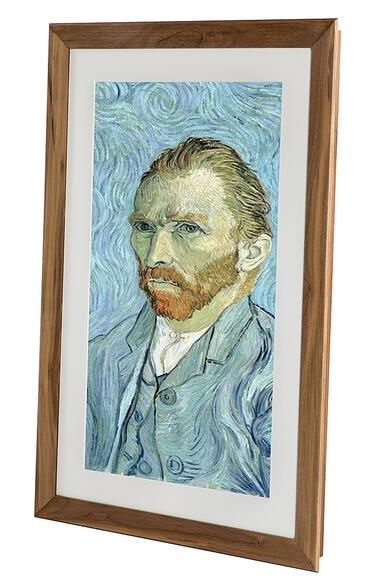

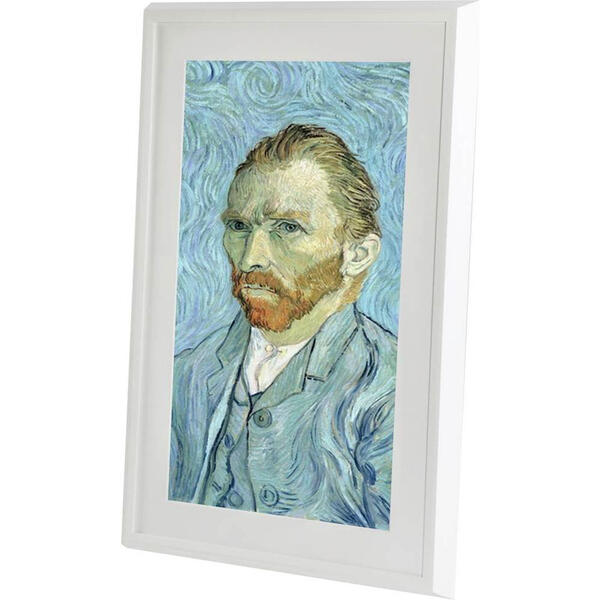

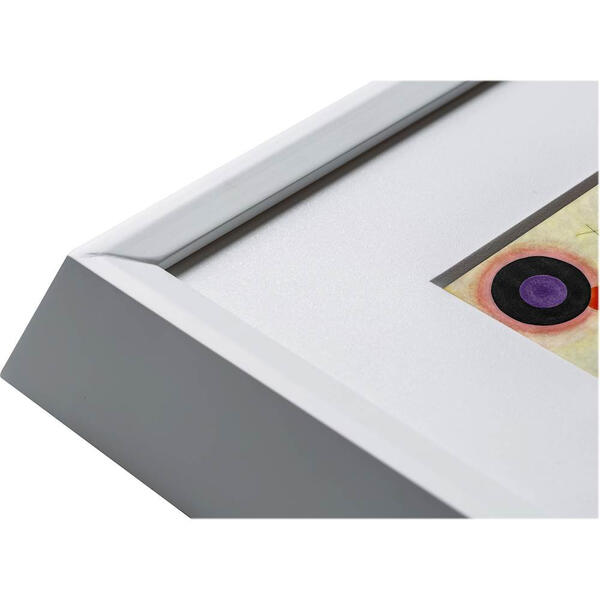

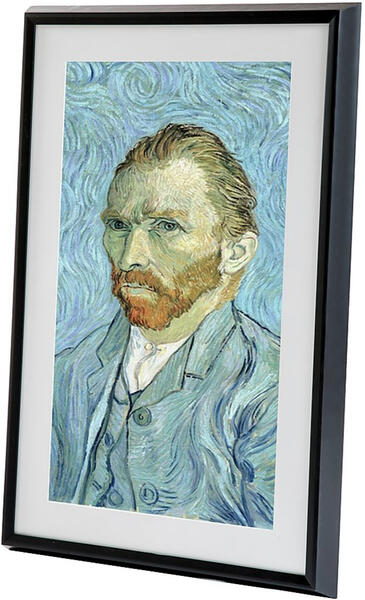

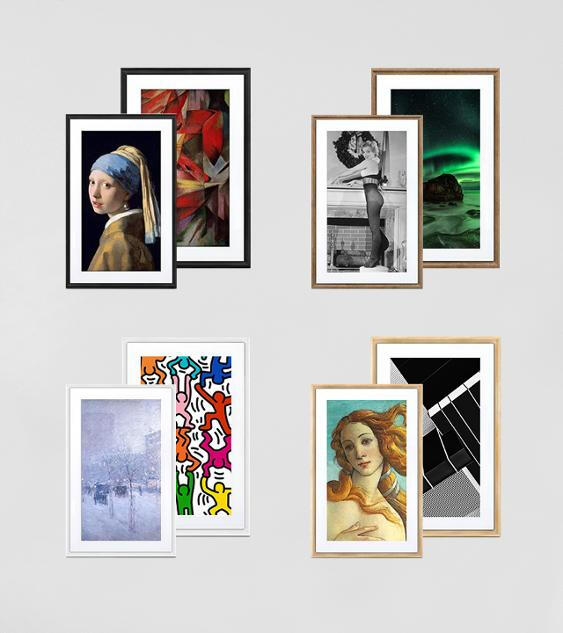

The wikipedia page describes the company better than I would:"Meural is an American technology company whose principal product is the Meural Canvas, a digital connected canvas built to showcase artwork and photography—both Meural- and user-provided. Through end-to-end production—a combination of proprietary hardware, software, and firmware—the digital frame is designed to look lifelike and textured."In short, Meural makes a device that displays art in a lifelike way and provides the user with licensed art from galleries and museums.Also notable is the way in which the device is controlled: while the user can control the interface from their smartphone, it also contains hidden gesture sensors that enable direct control.Acquired by Netgear in 2018.

Responsibilities

Redesign v1.0 for higher-volume manufacturing

Oversee transition from US-based manufacturing to Shenzhen-based manufacturing

Act as Operations Lead (ensure that assembled devices make it through US customs, handle freight communications, that devices are compliant with international markets, that shipments to retailers are made on time, invoice retailers, etc.)

Oversee HW development of v2.0 and v3.0 devices (perform ME, coordinate ID, EE, FW teams)

Collaborate with executive leadership, product teams, marketing teams, curatorial teams to determine product requirements

Ensure that stakeholders understand product status at all times

Expand product line with additional devices and accessories

Reduce costs through new and redesigned components

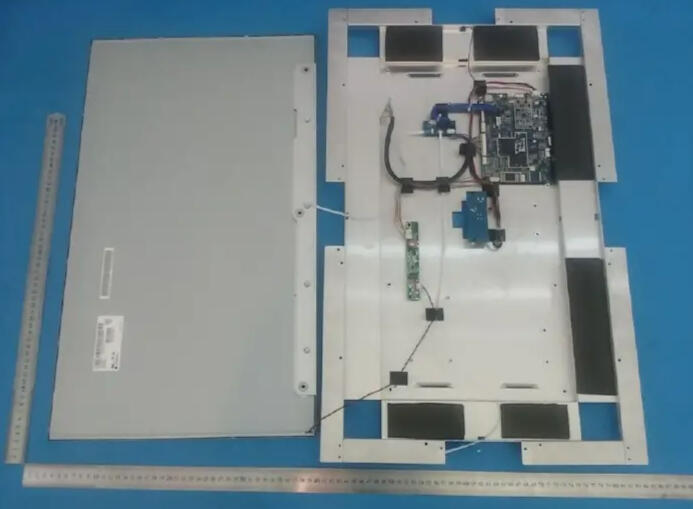

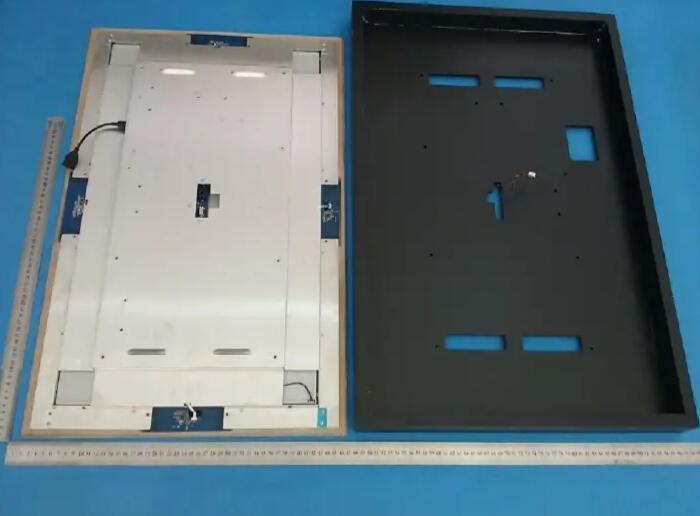

Meural v1.7

My first tasks when arriving at Meural involved transferring production overseas (instead of a barn in Pennsylvania) and redesigning for manufacturing.

Meural v2.0

With production of the Canvas underway, it was time to develop a sequel that incorporated lessons learned from the previous version.

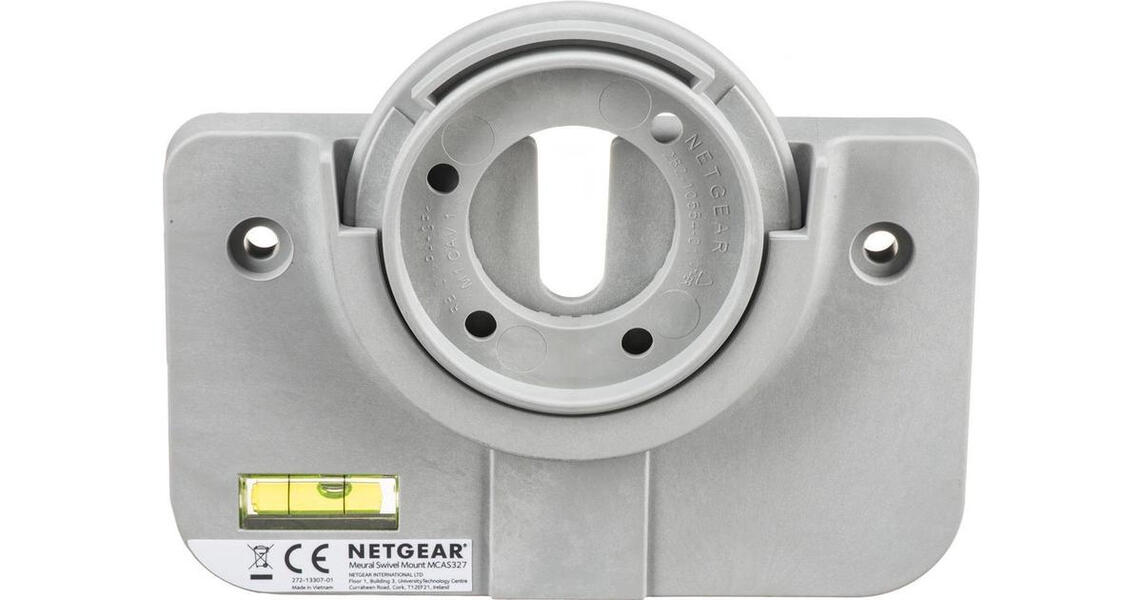

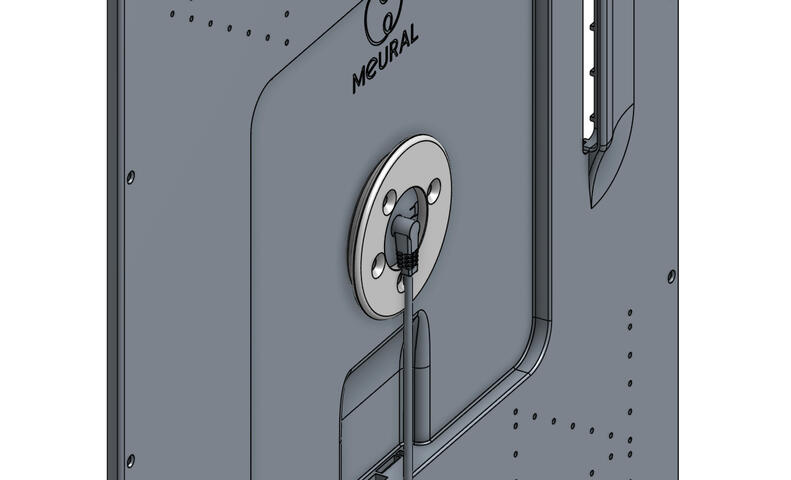

Rotating Wall Mounts

Meural v2.0 was designed to have the ability to rotate orientations on the wall, but this feature was removed to keep production deadlines.Instead, we took time to develop a better solution and release it as an accessory (with a high attach-rate).For v3.0, we redesigned the mount to make it cheaper and far easier to use.Read on for more info on each version.

Netgear Acquisition

In 2018, Netgear opted to pick up Meural, causing us to become "Meural, Powered by Netgear".My own role switched from "Product Manager" to "Meural Program Manager" and "Senior Mechanical Engineer".I was no longer the sole Mechanical Engineer, though I was responsible for approving all designs and Engineering Verification Testing, Design Verification Testing, and Production Verification Testing components.As the "Program Manager", I also developed new accessories, kept leadership in the know through regular updates, and managed projects using Smartsheets.Having new ME help enabled us to create a more interesting next Meural version, create multiple sizes of canvases, and branch out into more accessories.While I'm no longer at Netgear, they're still going strong (with even more new sizes) and were primed for success during NFT-mania.

Meural v3.0 (aka Canvas 2)

With the new resources from Netgear, we created a version of the Digital Canvas that incorporated many of our dream features.We also developed a smaller, entry level version in order to get on even more walls.

Other Meural Projects

Beyond creating Canvases and accessories, I had a wide range of attempted projects and other responsibilities.

Meural v1.7 Development

Contents

Baseline and New Requirements

When I arrived at Meural, they had launched the very first 27" version of the Digital Canvas.There were three options for customizability: two "low end" Canvases with painted White Poplar frames and one higher end Maple "lightbox" frame.Outside of the wood frames, the construction was CNCed Medium Density Fiberboard (MDF) for the mat board and sheet metal for the structural components.

Production was happening on a farm in Lancaster, PA that also made furniture.With that, my first goals at Meural were:

| Requirement | Reason |

|---|---|

| Move production from Lancaster, PA to Shenzhen, China | Cost |

| Redesign interior components to incorporate injection molding | Cost |

MDF to Plastic Mat Board

Creating an injection molded shape that mimicked an MDF mat board was relatively easy.The two challenges that came from this were:1) Molding sink marks appeared in the long, thin, flat areas of plastic. These pockets were required in order to fit the gesture sensors, so adding ribs was not an option.2) Plastic doesn't look or feel the same as a regular mat board, which typically are made of canvas, cardboard, or foamcore.In both of these cases, mold texture and an additional coat of paint solved the problem.

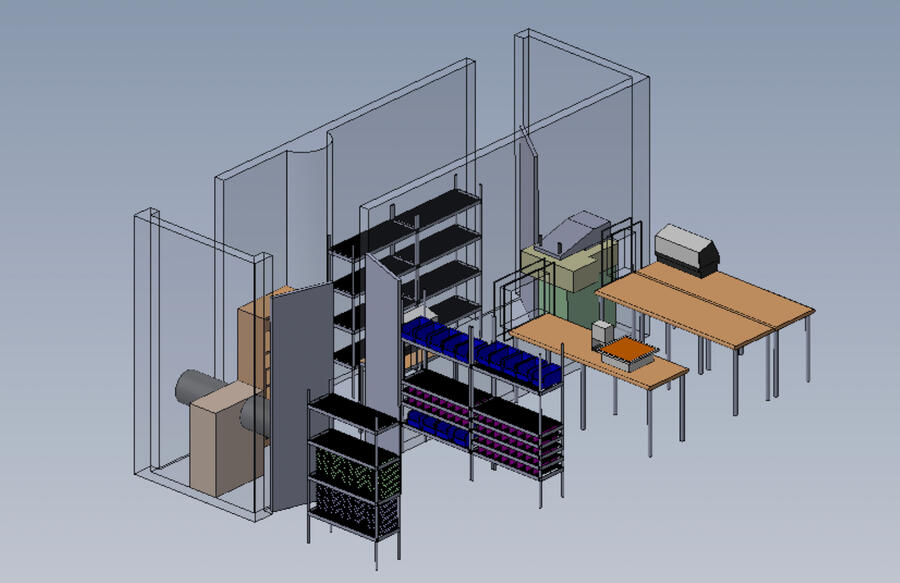

Moving to Shenzhen

I spent time at the farm in PA documenting the assembly and QA processes and cycle times. Communicating with our partners in Shenzhen, I was given the dimensions and capabilities of our manufacturing space.Applying process development skills I gained at SOLS and Boyd Coatings, I developed a layout and assembly processes (and sub-assembly processes) that I predicted would decrease assembly time by 50%. With the language barrier, these processes were developed with images that eliminated the need to read.To kick off production, I went to Shenzhen to oversee processes, approve part samples, and work on assembly to speed things up where necessary.

Other OperationsBeyond supervising manufacturing, I was also responsible for getting the product back into the USA (managing customs brokers), sourcing and managing contract manufacturers, and ensuring we were compliant with Canadian regulations and taxes.

Rotating wall mounts

Contents

Why should the Canvas rotate?

Strictly speaking, the Canvas didn't need to rotate. It just needed to change orientation while still on the wall.Meural users had the option of orienting the canvas either horizontally (like a landscape image) or vertically (like a portrait image). Most galleries only worked in one orientation.We noticed that customers were typically only viewing half of the galleries they had available.Looking at the data more closely, it turned out that users were installing the Canvas in one orientation and then never taking it down, limiting their available galleries.

Why wouldn't we use an off-the-shelf piece of hardware instead of making our own?

There are plenty of VESA mounts that rotate, but they were a bad solution for two reasons.1) VESA mounts tend to mount directly to the LCD panel for strength reasons. Our LCD panels did not have hardware for mounting VESA equipment.2) VESA mounts hold the device several inches off the wall. This is fine for televisions and monitors. Art is held as close to the wall as possible.

Why is the wall mount sold as an accessory instead of being part of the Digital Canvas?

The mount was always intended to be a part of the v2.0 Canvas.Upcoming deadlines meant that we needed to freeze features and head into production.The R&D that went into making the mount at the time was taking too long. Leadership also required that the wall mount be on this version, and not a future version.I was able to make the case that getting the wall mount right was critical, so I really needed more time. The compromise was to pause R&D, leave the Canvas design with a place to attach the mount, and create an accessory as soon as the v2.0 Canvas was in production.

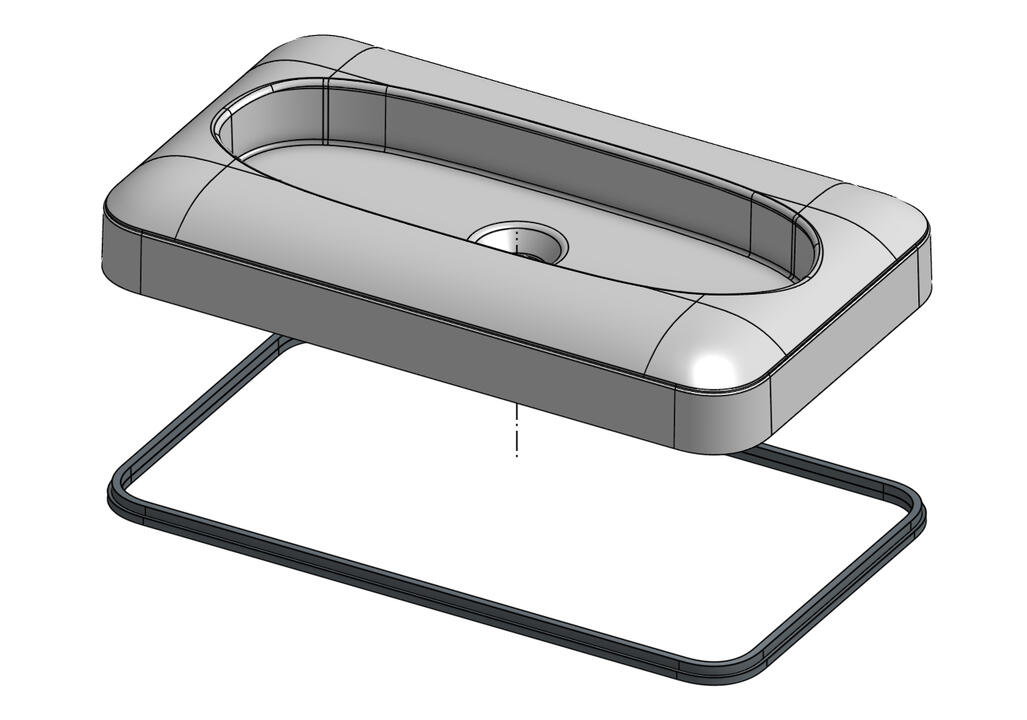

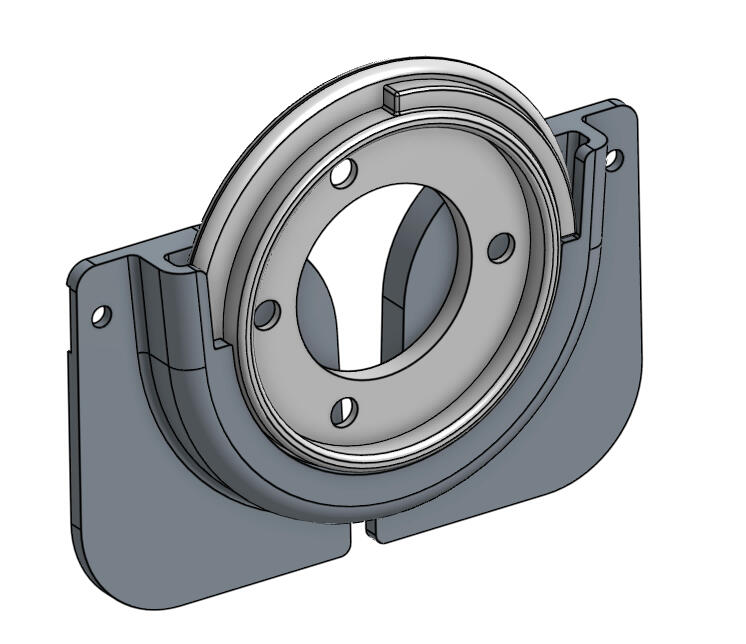

Rotating Mount v1

The original concept for the mount involved a plastic component that stuck to the wall and an aluminum "donut" that attached to the back of the canvas.The plastic mount had a lock that would create a massive gunshot-like "BANG" noise every time it changed orientation. This was not a great UX.Having reoriented the internal components of the Canvas, the center of gravity wound up directly in the center. It turned out that we didn't really need a locking mechanism at all, since the Canvas would stay in the position it was moved in.

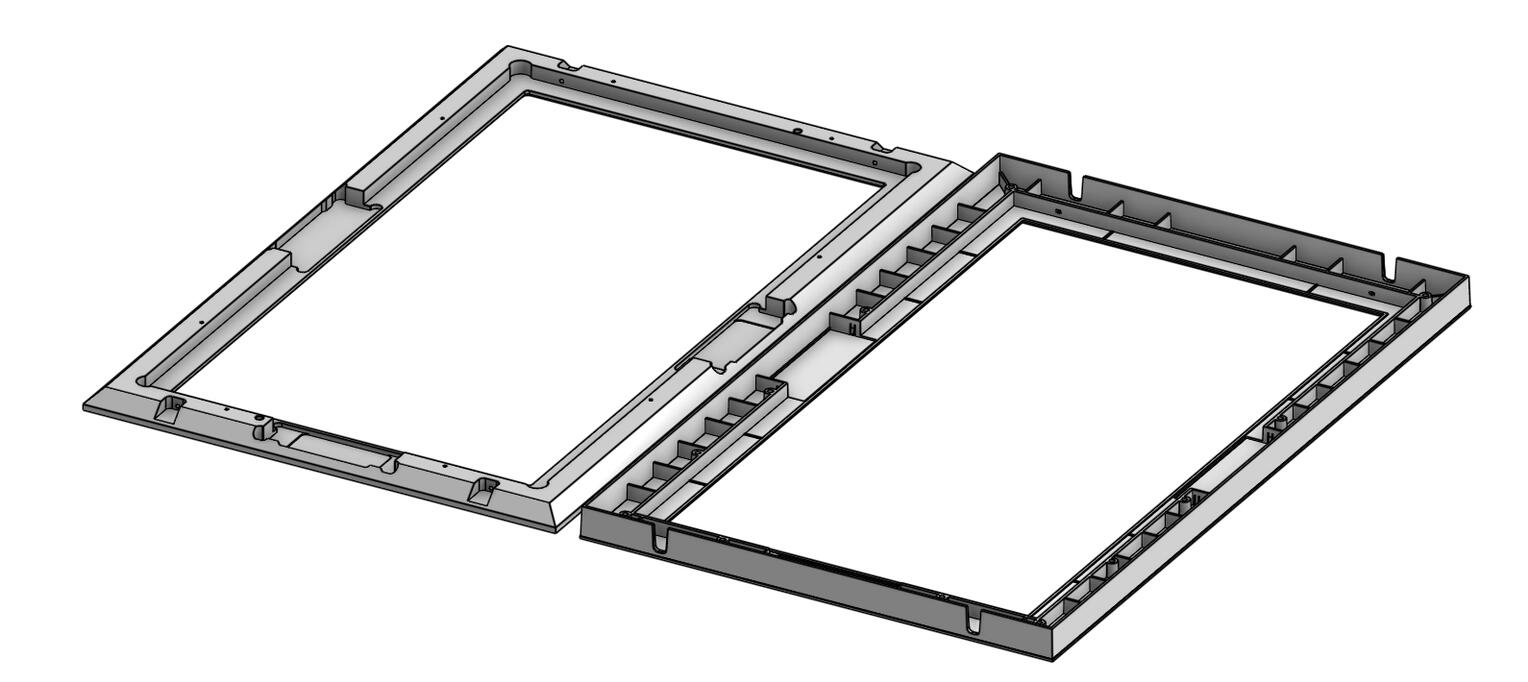

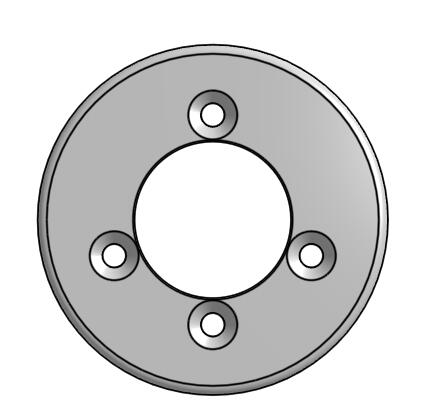

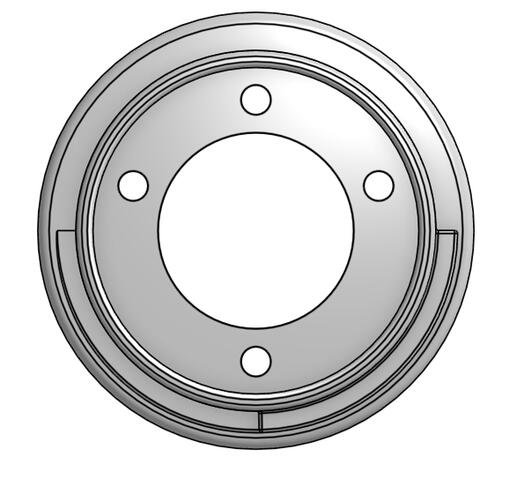

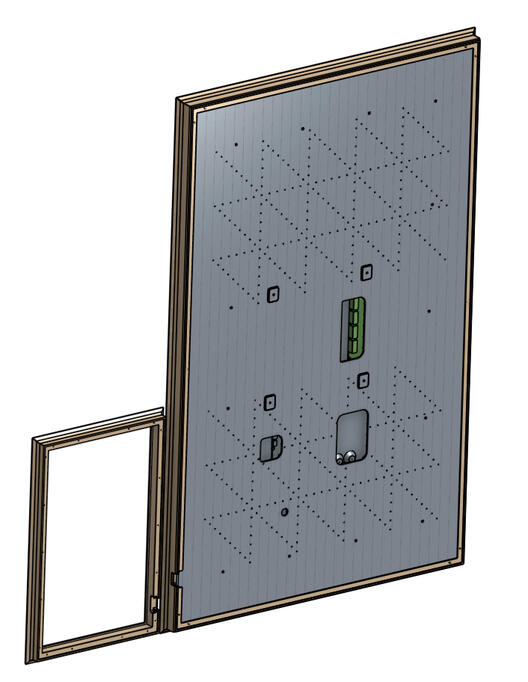

The first redesign of the mount involved two pieces:1) a "Donut" that attached to the Canvas with self-tapping screws. Like the Canvas backplate, it was molded out of Polycarbonate. The four holes were keyed so that it could only be installed one way. This Donut included a feature that stopped rotation after 90 degrees.2) The wall mount. This cast aluminum part attached to the wall with anchors.This design was mostly functional. The mount stuck to the Canvas, it rotated, and the Canvas stayed in place when rotated.However, if plugged into the wall, the power cable would creep up with each rotation. Eventually, this would cause the Donut to dislodge and the Canvas was unable to stay oriented. Plugging in the Canvas was pretty typical, so we needed a fix.

The quick fix here was another piece of aluminum that went around the original wall mount.Threading the cable through both mounts before plugging it in kept the cable seated 100% of the time.This worked, and the mount sold really well (with nearly 100% attachment). That said, having multiple mount components was not ideal, and became a critical piece to fix for the next version of the wall mount.

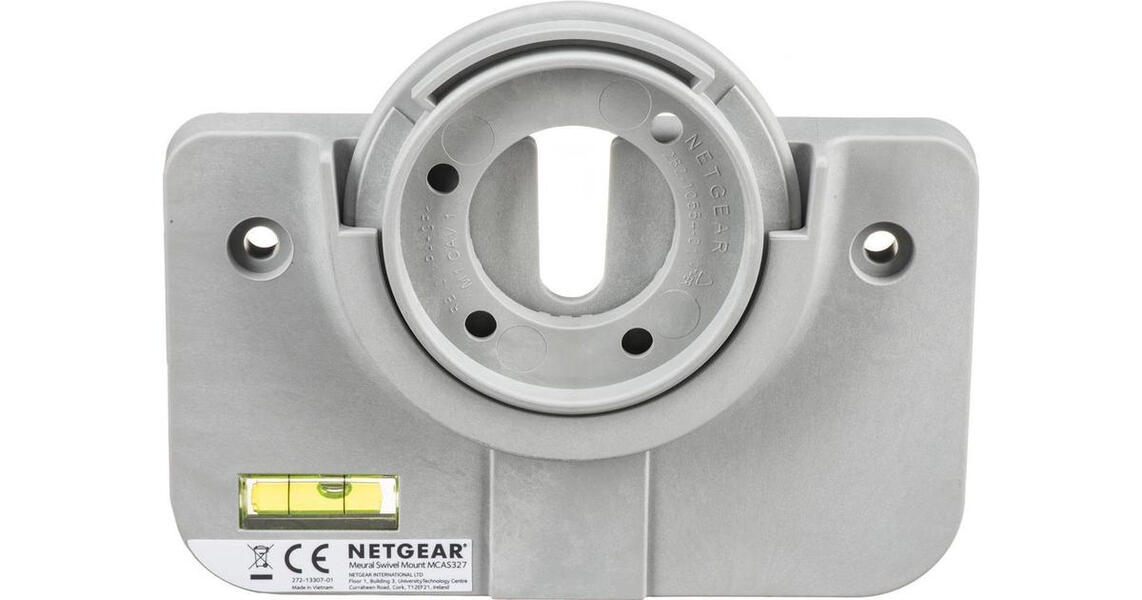

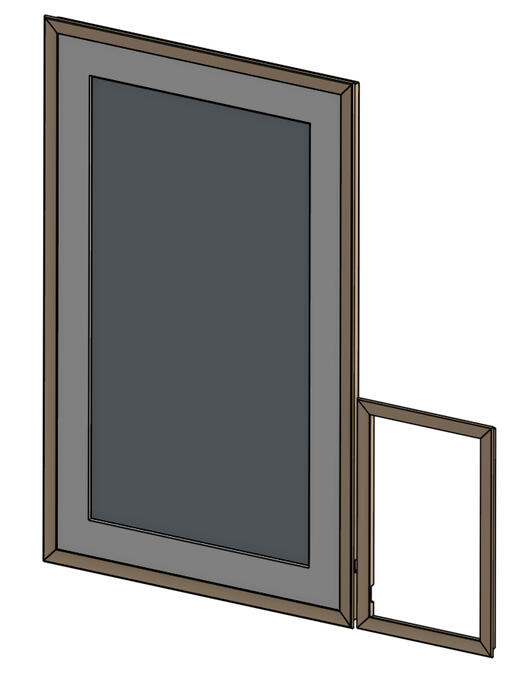

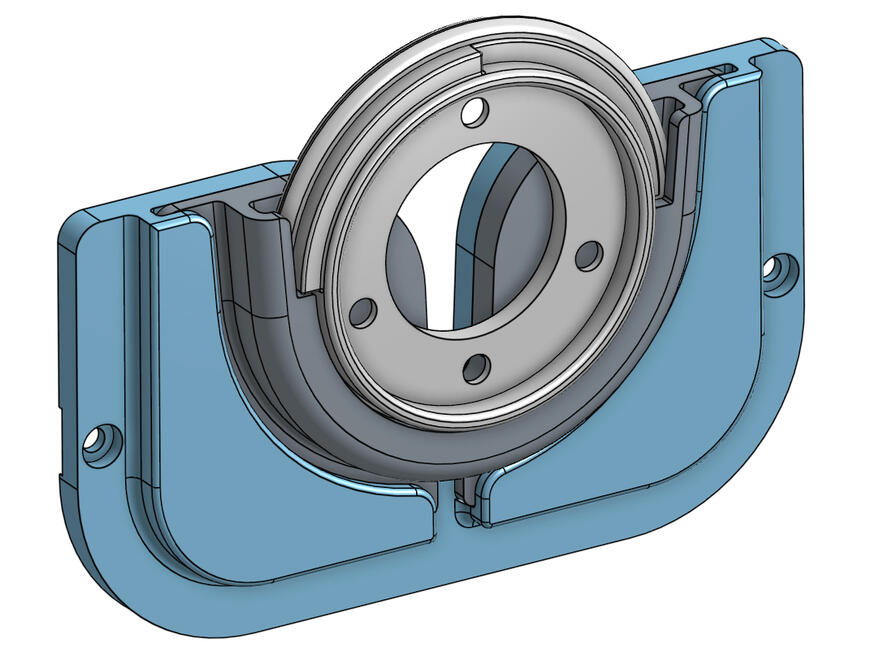

Rotating Mount v2

With the help of Netgear, we created a much superior version of the wall mount.This mount used the same Donut, but managed the cable entirely differently (thanks in part to the redesigned v3.0 Digital Canvas.Instead of plugging the power cable into the direct center of the Canvas, it was plugged in elsewhere and threaded to the center of the Canvas. This made sure that the cable never creeped into the Wall Mount and reduced the need for an entire component.In addition to making the cable easier to use, this version included two other features:1) Totally injection molded design, lowering costs

2) An integrated level, making mounting to the wall much easier

Meural v2.0 Development

Contents

Requirements Wish List

Alongside company leadership, the curatorial team, product team, and marketing team, we created a wish list of requirements.

| Requirement | Reason |

|---|---|

| A distinctly "Meural" design | There are dozens of digital frames available, and we needed Meural's to stand out. |

| Capable of both "Vertical" and "Horizontal" orientation without being removed from the wall | Galleries were meant to be viewed in either horizontal or vertical orientation. Users were only viewing art in the orientation they originally installed the Meural. |

| A "Sleep/Shutdown" button | "Sleeping" the device took too many steps. "Shutdown" required unplugging the Meural. |

| Reduced Cost of Goods Sold (COGS) through more injection-molded components and new electronics | Decreasing costs for a young startup. |

| User access to the USB, HDMI, and MicroSD ports without removing the canvas from the wall | Adding personal art to the device required removing it from the wall. |

| Removable frames | Increased personalization. |

| Light-Up indicators on the gesture control boards | The gesture boards were hidden, increasing the Meural learning curve. |

| Shipping by September | To meet retailers' holiday deadlines. |

Hardware Constraints

It's worth noting that several of these requirements didn't make it into this version. We were starting development in January 2015 with plans to deliver the product by that Christmas. Our relationships with retailers required us to have inventory ready to go by September.Hardware development typically takes 18+ months. In order to ship on time, certain features had to go. The trick was to figure out what was critical for v2.0, what could wait for v3.0, and what could be launched as an accessory.

Winslow:

Leonora (White):

Leonora (Black):

On the Distinctly Meural DesignThis was the most critical aspect of the new version. There are dozens of digital frames available, and we needed Meural's to stand out.To get there, we surveyed local Industrial Designers, furniture designers, and graphic designers who could fit what we were looking for.Narrowing down to three of them, we offered each a paid month-long Request for Proposal. At the end of the process, we would hire the designer for a longer arrangement to finish the concepts.

On Deprecating Features

As mentioned, we simply had to get rid of certain features in order to ship on time.In order to figure out what was critical to include at launch, I created a matrix of what was most critical to include.We knew that the new design, Sleep/Shutdown button, and lower cost were musts. The "Light Up Indicators" and port access were less critical. We would need to include at least one of the remaining features:

Capable of both "Vertical" and "Horizontal" orientation without being removed from the wall

Removeable frames

We settled on including a rotating wall mount and decided that the removable/replaceable frames could wait for v3.

v2.0 Mechanical Design

More Details to come!

Meural V3.0 (AKA Canvas 2)

New, more distinct design

User access to the USB, HDMI, and MicroSD ports without removing the canvas from the wall

Removeable frames

More To Come!

Other Meural Projects

Contents

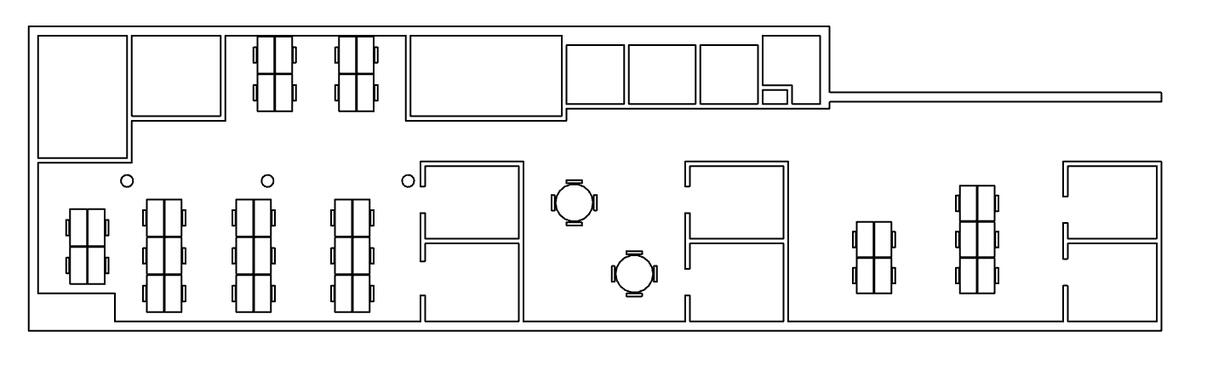

Office Layout

As the only one who could use CAD, I was responsible for creating layouts and figuring out where teams went as we expanded.

Retail Setups

When Meural started selling in major retailers, I worked with the product team to develop setups that worked within the retailer's constraints.

Really Big Meural (27" frame for scale)

We prototyped a 60" Digital Canvas that required a rotating VESA mount.This did exist, but apparently photos of it do not.

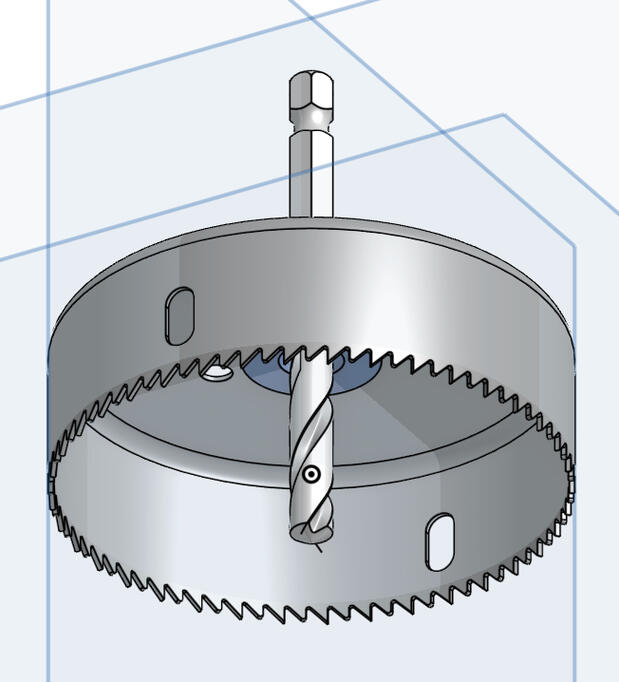

Hidden Power Cable

One of the most common complaints about Meural was that the power cable was visible. We looked into many ways of removing it — hiding it, a flat paintable cable, battery power — but nothing made it into production.The closest we got to was a kit that used a hole saw for creating holes in the wall, fish tape to draw the power cable up, and a grommet to make the holes look pretty.For an example of what we were going for, check out Amazon's offerings.

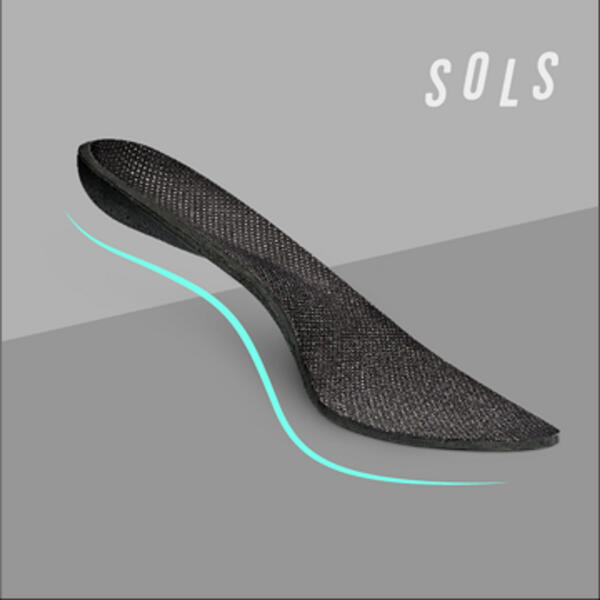

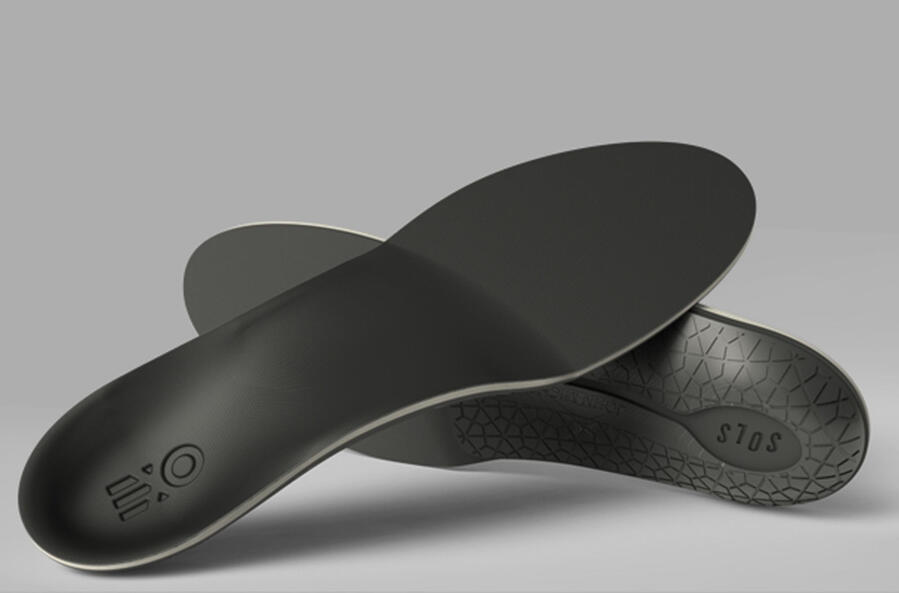

SOLS Systems (Now a Part of Aetrex)

Custom, 3D Printed Orthotic Insoles

Manufacturing Engineer

Contents

Accomplishments

Increased production efficiency by over 1000% through process optimization.

Skills Used

Mechanical Engineering

Solidworks/CAD

Arduino Prototyping

3D Printing

Process Design

Time Studies

Quality Auditing

Statistical Process Control

About SOLS

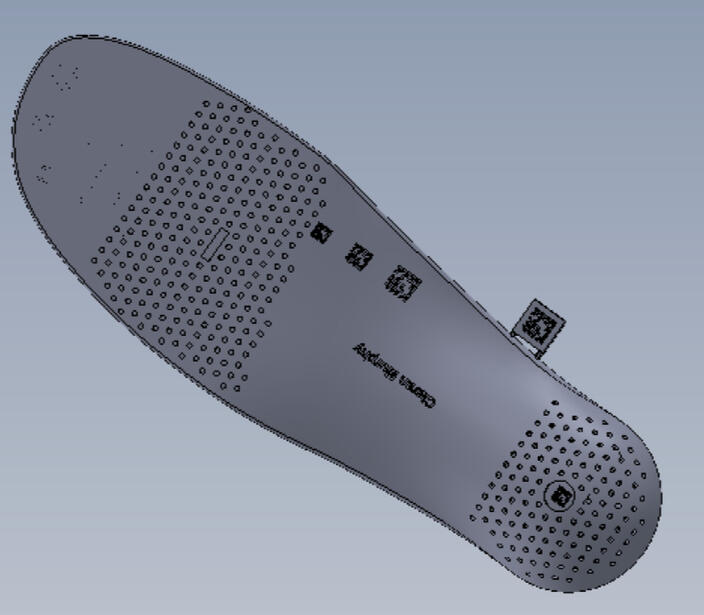

At Sols, we were making custom 3D printed orthotic insoles based on photos of clients’ feet.Photos were taken at the doctor’s office (and later, at home), models were generated by our software, SLS prints were made in Austin, TX, and post-processing (coatings, top covers, etc.) were applied at our facility in NYC.When I joined, the insoles were finished by artisans in a tiny artist’s studio. My initial responsibilities included:

Creating a repeatable manufacturing strategy for these custom products.

Moving manufacturing from the studio to our new office.

Writing SOPs and quality standards

Creating a coherent production line in our facility.

Increasing the quality of the coatings and adhesives through environmental control and ASTM standards.

Developing safety protocols based on OSHA standards and following them.

Identifying the greatest needs for process improvement through time studies and quality audits.

Integrating new equipment and new processes as new products were introduced.

Creating fixtures to test the life of SOLS and new products.

Eliminating "stepping" lines in the 3D prints through abrasion and coatings.

Factory Layout

While the factory was larger than an artist’s studio, space in NYC is always at a premium. The model abpve was frequently updated to ensure that employees could fit as processes were changed.In time, space became difficult to find, and carrying parts from one room to another became both a time bottleneck and a quality issue (due to workers bumping into one-another. To mitigate both of these issues, we cut holes into the walls:

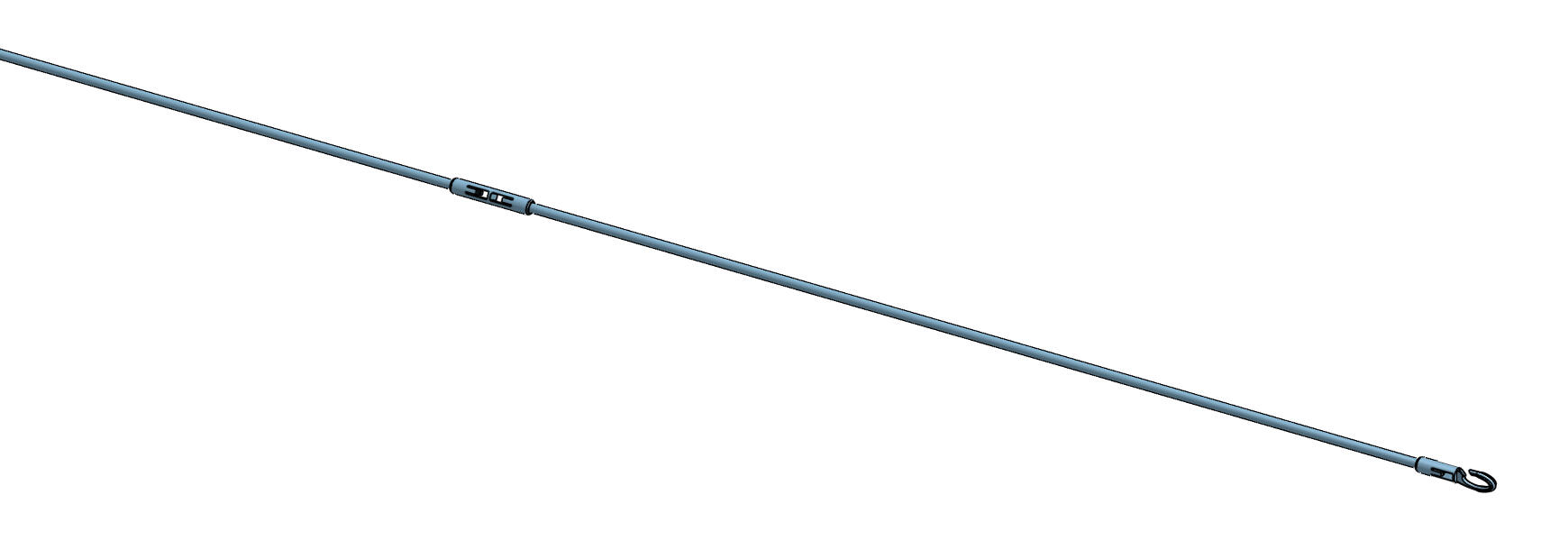

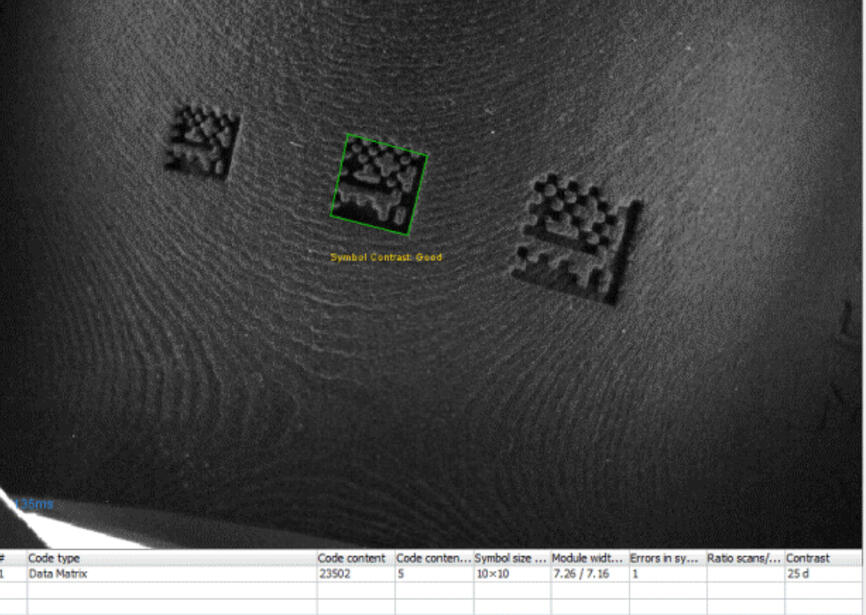

3D Printed Barcode

The single greatest process bottleneck was incoming inspection. Every insole was different, but it was difficult to tell them apart.Each insole had a customer's name and a part number. Checking this part number against a database showed the priority of the part and what kinds of coatings and materials were expected for it.Reading the number and comparing it took too long every morning. To remedy this, I worked with the product team to embed a datamatrix barcode in the print.The major challenge to this feature was that the 3D prints were all a single color. We played with placement on the part as well as barcode depth in order to develop structured lighting. This lighting caused shadows that the camera picked up as a barcode, eliminating this step as a bottleneck.

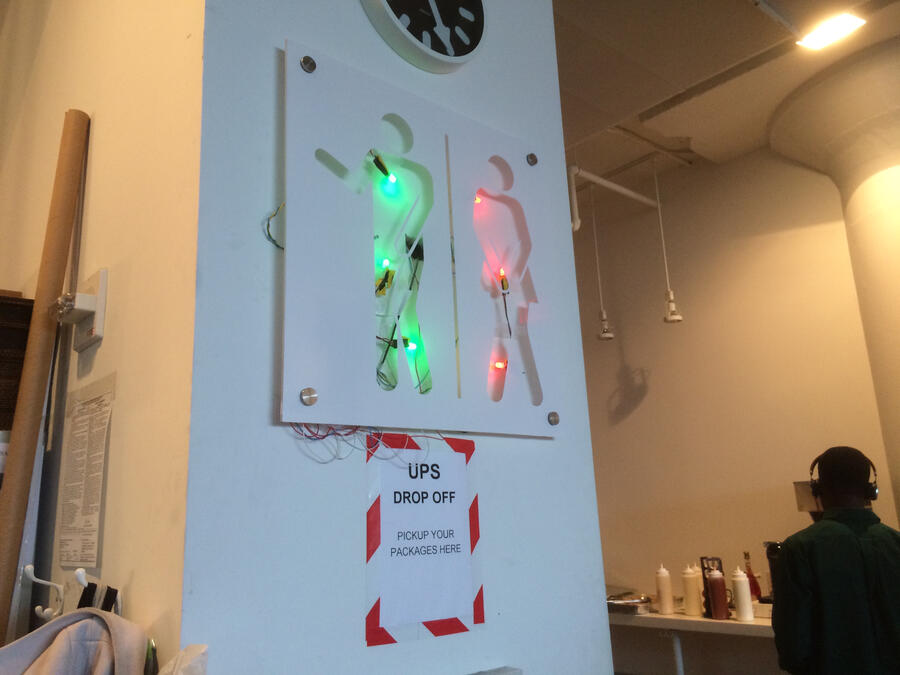

Pick to Light System

Sols ended up prioritizing a product that used less 3D printed material alongside a more rigid die-cut foam top cover (”Exosols”):

While die-cutting takes much less time than manually cutting material to size, finding the correct die was a time-consuming task. The machine operator had 60 dies to choose from, and they looked nearly identical to one another.To solve this issue, I built a pick-to-light system with materials we had sitting around. The combination of an Arduino, an old computer, addressable LEDs, a number pad, and a reset button made selecting the correct tool really easy.Originally, the process involved reading the product number from an insole, matching it to a piece of paper indicating the tool to use, and then finding the tool.After adding the Pick-to-Light system, the process involved reading the product number, typing it into the number pad, and selecting the tool that lit up. This cut this particular process’s time in half, eliminating it as a bottleneck.

Removing Stepping Lines

The lines that separate each 3D printing layer were considered "ugly", so we considered a number of ways to reduce or eliminate them.Initially this was through coating, which masked the issue.Later, we considered abrasive media, but that didn't appear to make a difference (at least on a reasonable timeframe).Sanding the parts was effective, but created so much heat that the parts melted.A colleage and I took a trip to a woodworking convention in Las Vegas to see what solutions existed. We needed a compliant sander that could curve around the arch of the insole that also had heat management.We found a rotary sander that did just that (using coconut husks to dissipate heat), and quickly integrated it into the line.

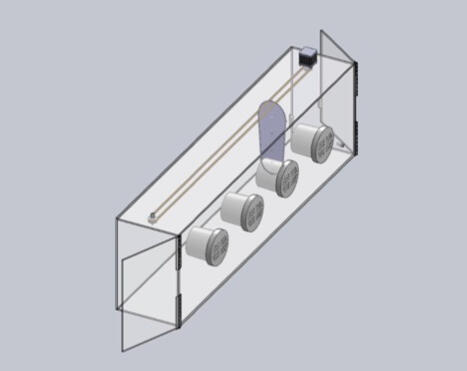

Drying Conveyor

Top cover materials were held using contact cement.This spray-on material took time to dry before adhering to the insole, causing a time bottleneck and a massing of parts.Gluing also occurred in a spraying room, while adhering occurred in another room.To reduce time and space required, I built a drying conveyor box. Four dehydrating fans kept the box at an ideal humidity level. A motor and chain along the top brought the parts from one room to the next.As the second photo indicates, this top cover became impossible to remove.

Restroom Occupency Monitor

Sols wound up growing to over 70 employees, while only having two restrooms.These restrooms were far away from where anyone worked. When the time came, lines would form as employees would check on the restroom and decide not to walk all the way back to their desks.During a company hackathon, I teamed up with another employee to add an airplane-lavatory style occupancy monitor. Our supplies included magnetic reed switches, hundreds of feet of wire, and some RGB LEDs. It’s not pretty, but it worked, led to a meaningful increase in productivity, and won us the hackathon.

Boyd Coatings Research (Now a part of precision coatings)

Process Design and Factory Automation

Process Engineer

Contents

Accomplishments

Increased production line efficiency by over 70% through automation.

Reduced airborne contamination by 6%.

Skills Used

Mechanical Engineering

Solidworks/CAD

Process Design

Applications Engineering

Quality Auditing

Statistical Process Control

Time Studies

About Boyd Coatings

This fluoropolymer (Teflon) coating facility specialized in coating medical wires for stents, but was looking to expand.

My Responsibilities

Speaking with customers to understand their coating requirements.

Translating customer requirements into coating processes in JobBoss ERP.

Ensuring that processes were understood, even with language barriers.

Designing fixtures and masks in Solidworks.

Performing Statistical Process Control audits to ensure coating quality.

Measuring particle counts in the facility. Recommending ways to eliminate contamination.

Integrating automation into the facility.

Automation

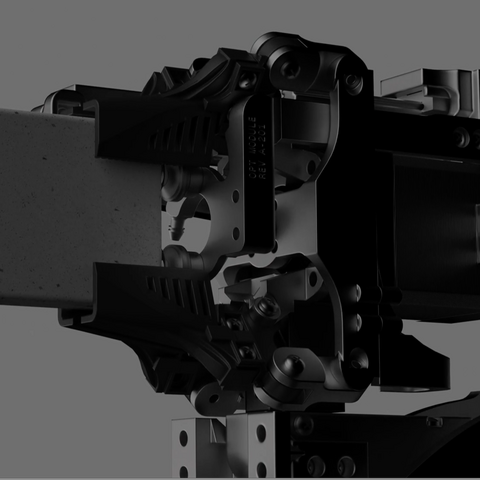

While the role was for a process engineer, I was actually hired to bring on more automation. The plant had a single ABB robot, but wanted more.My goal was to integrate a new Fanuc spraying robot. While we waited, I needed to add smaller robots wherever processes could benefit.Fanuc Robot

I added a Fanuc Paintmate 200iA along with turntable-based fixturing and loading and unloading areas that required no light curtains or cages.Unfortunately, no photos of this outfit exist.

Small Robots

With the long lead-time for industrial robots, I also found ways to get quick wins.For especially low-cost jobs, I built a small robot based on the forms of toy robot arms.This 6 degree-of-freedom was designed with sheet metal components, 7 aluminum-toothed servos, a Graco spray gun, and a stepper motor-driven lead screw (to enable coating of many parts on a fixture).The robot was programmed in Ruby/Flowstone.From what I understand, it was in use for years after I left.

Machflow Energy

A Scaleable, Novel Air Conditioner

R&D Engineer

Contents

Accomplishments:

Completed Proof-of-Concept Device

Skills Used:

Mechanical Engineering

Solidworks/CAD

CNC Prototyping

Manual Machining

Circuit Design

About Machflow

My first role out of college got me hooked on venture-backed startups.Machflow's mission was to build an environmentally-friendly and scalable air conditioning system through a combination of the Bernoulli effect and rare gas mixtures.Gas cools as it flows through a Venturi nozzle (by ~75°C). Under typical scenarios, a boundary layer forms in the gas, keeping the nozzle warm. Machflow's addition of rare gas mixtures broke through this boundary layer, allowing the nozzle to cool and efficiently changing the surrounding temperature.In theory, the system could work at the scale of laptop CPUs all the way to large buildings (and beyond).In this role, I would be given curves generated by the Chief Science Officer, turned those curves into nozzle designs, and then machine (or print) the nozzles. Frequently, we also integrated sensors and heating elements, requiring high-temperature and composite elements.

Responsibilities

In this role, I would be given curves generated by the Chief Science Officer, turned those curves into nozzle designs, and then machine (or print) the nozzles. Frequently, we also integrated sensors and heating elements, requiring high-temperature and composite elements.

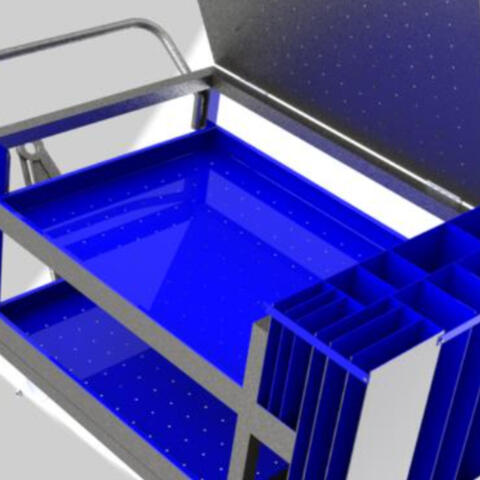

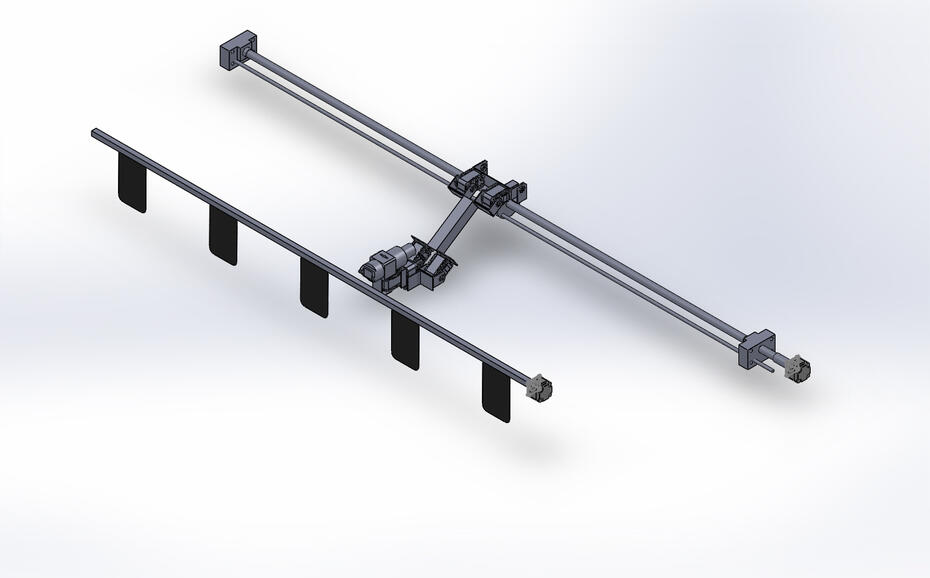

Caterpillar

Transport Carts for Production Lines

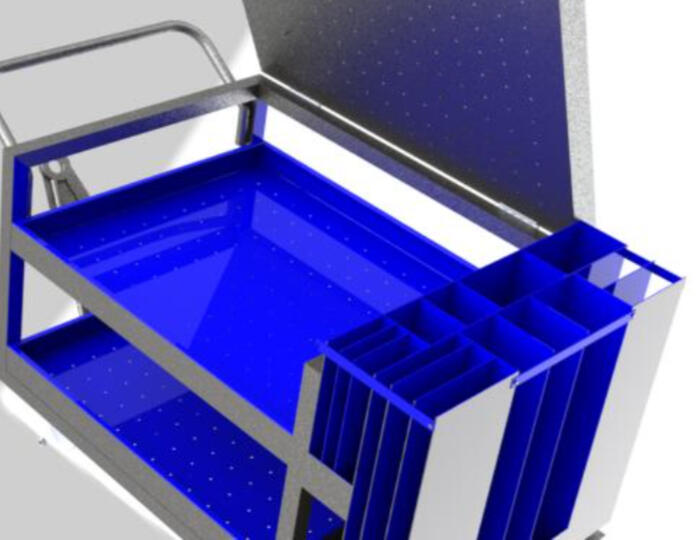

Major Qualifying Project (MQP)

Wuhan, China

Contents

Accomplishments:

33% Increase in space efficiency

100% reduction in quality issues

"Best Manufacturing MQP Award"

Skills Used:

Mechanical Engineering

Solidworks/CAD

Lean Manufacturing

Before:

Overstuffed Cart

Excessive Protection

Delamination

After:

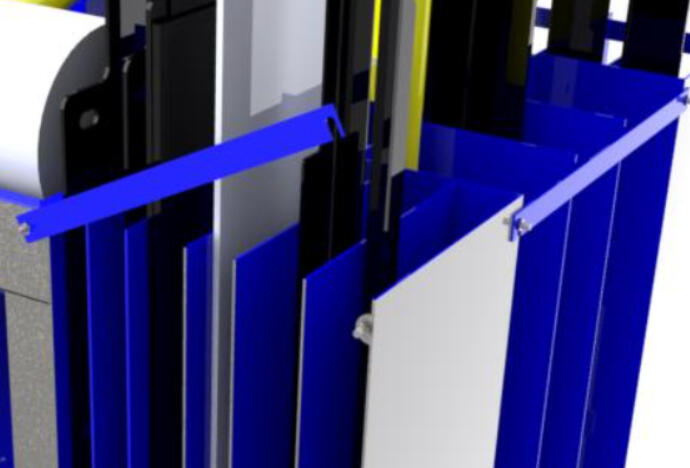

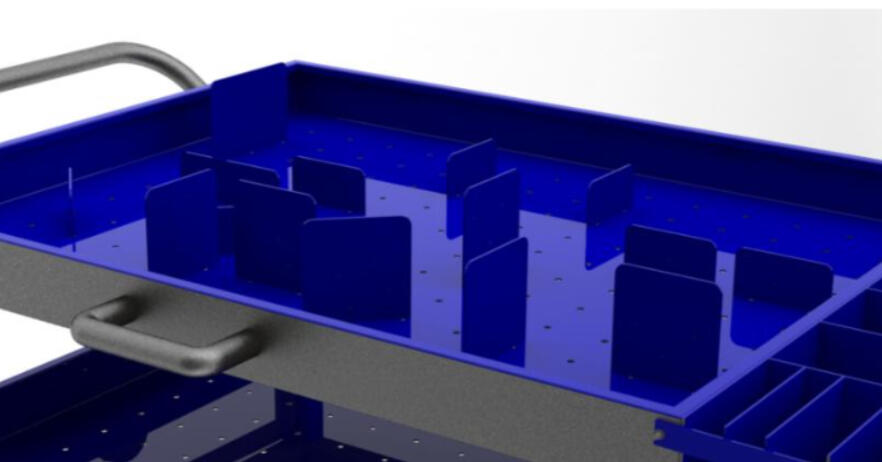

Rotating Shelf

Gates

Tabs

The Problem

My senior project at WPI involved redesigning factory equipment for Caterpillar.Caterpillar's Chinese factories utilized "Kanban Kit Carts" to move material around the production floor. These carts are common in factories, but caused quality issues for them.Due to their size and shape, parts would collide. Contamination also caused existing protective materials to break off the carts. These issues led to damage and increased rework. Beyond part damage, the ergonomics of the carts required operators to either bend down or stretch in ways that led to injury.

Our Solution and Results

Our brief involved increasing space efficiency (so parts had space), improving ergonomics, and introducing better cushioning materials to the product.Through the addition of a grid layout and replaceable tabs, we created fixtures that enabled the components to stay in place and increased space efficiency by over 33%. A spray-on elastomer coating also eliminated adhesive issues. Adding a rotating shelf enabled parts to be stored at more ergonomically appropriate heights.This project was considered to be a success, and my team won "Best Manufacturing MQP of the Year".

NASA Ames Research Center

Lunar MicroRover Project

Intern

Accomplishments:

Ka-band Antenna Design for Earth to lander communication

UHF-band Antenna research for lander to rover communication

Skills Used:

Electrical Engineering

Project Managment

The goal of the LMR project was to send clusters of inexpensive rovers to the moon. While the robots never left Earth, it was a great view of applying lean principles to non-traditional projects.